Large-Sample Confidence Intervals for a Mean

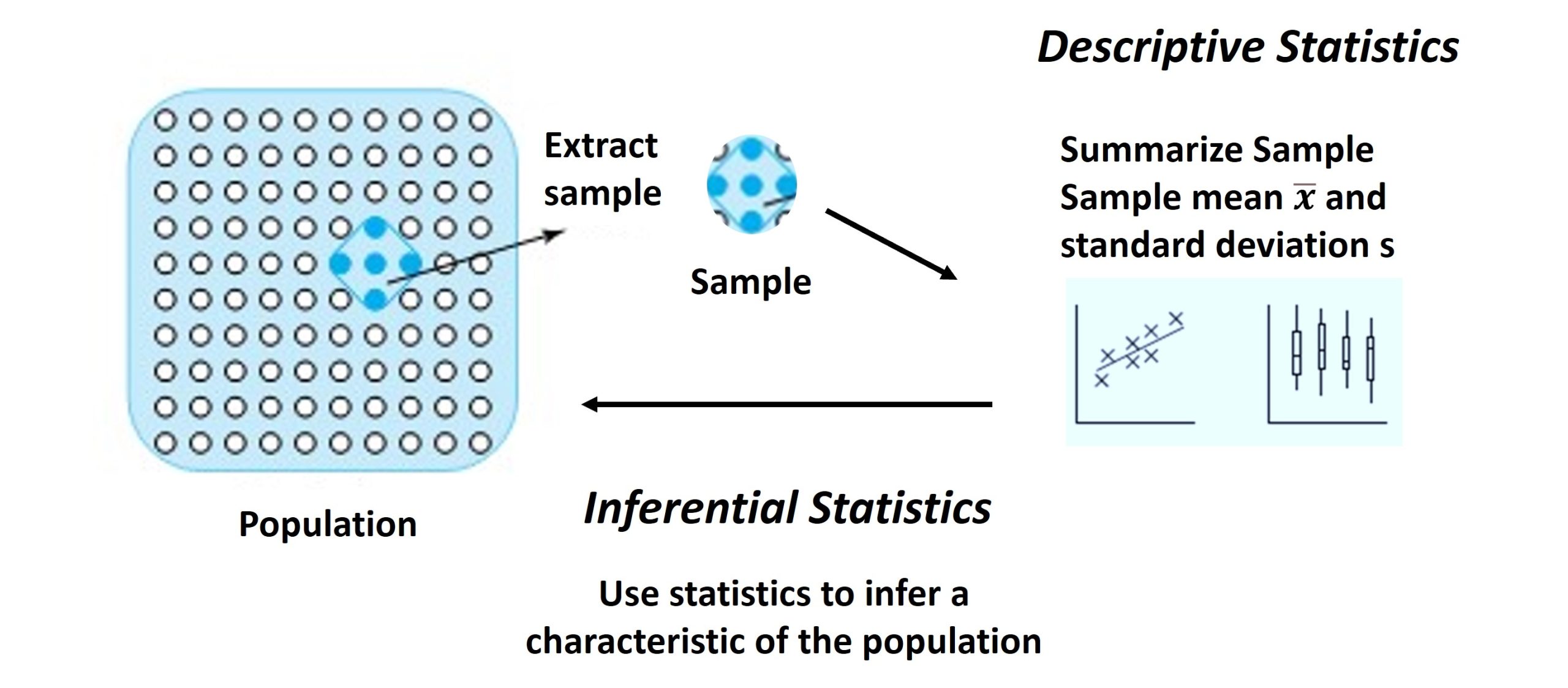

Many important engineering applications of statistics fit the following standard mold. Values for parameters of a data-generating process are unknown. Based on data, the object is

- identify an interval of values likely to contain an unknown parameter (or a function of one or more parameters) and

- quantify “how likely” the interval is to cover the correct value.

.

For example, a piece of equipment that dispenses baby food into jars might produce an unknown mean fill level, µ. Determining a data-based interval likely to contain µ and an evaluation of the reliability of the interval might be important. Or a machine that puts threads on U-bolts might have an inherent variation in thread lengths, describable in terms of a standard deviation, σ . The point of data collection might then be to produce an interval of likely values for σ , together with a statement of how reliable the interval is. Or two different methods of running a pelletizing machine might have different unknown propensities to produce defective pellets, (say, p1 and p2). A data-based interval for p1 − p2 , together with an associated statement of reliability, might be needed

.

DEFINITION 5.1.1.1 Confidence Interval

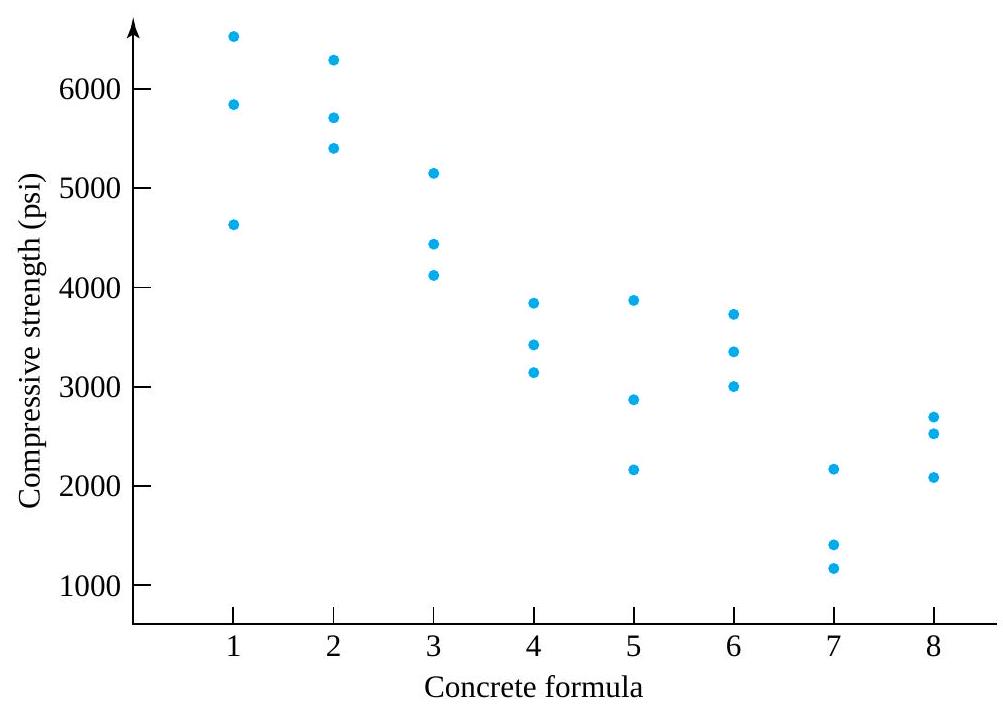

A confidence interval for a parameter (or function of one or more parameters) is a data-based interval of numbers thought likely to contain the parameter (or function of one or more parameters) possessing a stated probability-based confidence or reliability.

This section discusses how basic probability facts lead to simple large-sample formulas for confidence intervals for a mean, µ. The unusual case where the standard deviation σ is known is treated first. Then parallel reasoning produces a formula for the much more common situation where σ is not known. The section closes with discussions of three practical issues in the application of confidence intervals.

A Large-n Confidence Interval for  involving

involving

The final example in Chapter 4.2.2.4 involved a physically stable filling process known to have a net weight standard deviation of σ = 1.6 g. Since, for large n,thesample mean of iid random variables is approximately normal, the final example of Chapter 4.2.4 argued that for n = 47 and

= the sample mean net fill weight of 47 jars filled by the process (g)

= the sample mean net fill weight of 47 jars filled by the process (g)

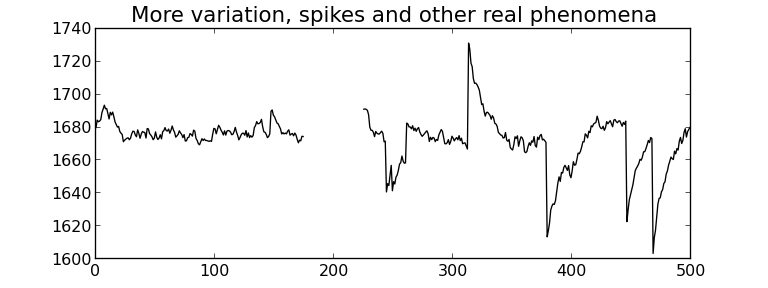

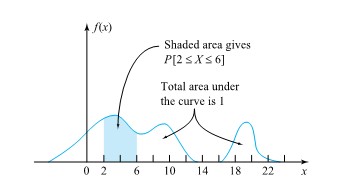

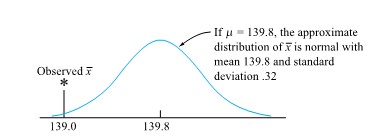

here is an approximately 80% chance that  is within .3 gram of µ. This fact is pictured again in Figure 5.1.1.1.

is within .3 gram of µ. This fact is pictured again in Figure 5.1.1.1.

Figure 5.1.1.1 Approximate probability distribution for x¯ based on n = 47

Notation ConventionsWe need to interrupt for a moment to discuss notation. In Part 4, capital letters were carefully used as symbols for random variables and corresponding lowercase letters for their possible or observed values. But here a lowercase symbol,  has been used for the sample mean random variable. This is fairly standard statistical usage, and it is in keeping with the kind of convention used in earlier Parts. We are thus going to now abandon strict adherence to the capitalization convention introduced in Chapter 4. Random variables will often be symbolized using lowercase letters and the same symbols used for their observed values. The Chapter 4 capitalization convention is especially helpful in learning the basics of probability. But once those basics are mastered, it is common to abuse notation and to determine from context whether a random variable or its observed value is being discussed.

has been used for the sample mean random variable. This is fairly standard statistical usage, and it is in keeping with the kind of convention used in earlier Parts. We are thus going to now abandon strict adherence to the capitalization convention introduced in Chapter 4. Random variables will often be symbolized using lowercase letters and the same symbols used for their observed values. The Chapter 4 capitalization convention is especially helpful in learning the basics of probability. But once those basics are mastered, it is common to abuse notation and to determine from context whether a random variable or its observed value is being discussed.

.

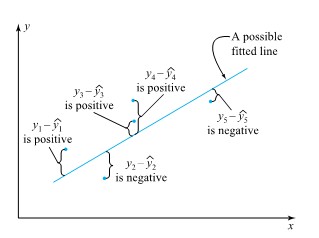

The most common way of thinking about a graphic like Figure 5.1.1.1 is to think of the possibility that

5.1.1.1

in terms of whether or not  falls in an interval of length 2(.3) = .6 centered at µ. But the equivalent is to consider whether or not an interval of length .6 centered at

falls in an interval of length 2(.3) = .6 centered at µ. But the equivalent is to consider whether or not an interval of length .6 centered at  falls on top of µ. Algebraically, inequality (5.1.1.1) is equivalent to

falls on top of µ. Algebraically, inequality (5.1.1.1) is equivalent to

5.1.1.2

which shifts attention to this second way of thinking. The fact that expression (5.1.1.2) has about an 80% chance of holding true anytime a sample of 47 fill weights is taken suggests that the random interval

5.1.1.3

can be used as a confidence interval for µ, with 80% associated reliability or confidence.

Suppose a sample of n = 47 jars produces  = 138.2 g. Then expression (5.1.1.3) suggests that the interval with endpoints

= 138.2 g. Then expression (5.1.1.3) suggests that the interval with endpoints

138.2 g  .3 g

.3 g

(i.e., the interval from 137.9 g to 138.5 g) be used as an 80% confidence interval for the process mean fill weight.

It is not hard to generalize the logic that led to expression (5.1.1.3). Anytime an iid model is appropriate for the elements of a large sample, the central limit theorem implies that the sample mean  is approximately normal with mean µ and standard deviation σ/√n. Then, if for p >.5, z is the p quantile of the standard normal distribution, the probability that

is approximately normal with mean µ and standard deviation σ/√n. Then, if for p >.5, z is the p quantile of the standard normal distribution, the probability that

5.1.1.4

is approximately 1 − 2(1 − p). But inequality (5.1.1.4) can be rewritten as

5.1.1.5

and thought of as the eventuality that the random interval with endpoints

EXPRESSION 5.1.1.6 Large-Sample Known  Confidence Limits for

Confidence Limits for

brackets the unknown µ. So an interval with endpoints (5.1.1.6) is an approximate confidence interval for µ (with confidence level 1 − 2(1 − p)).

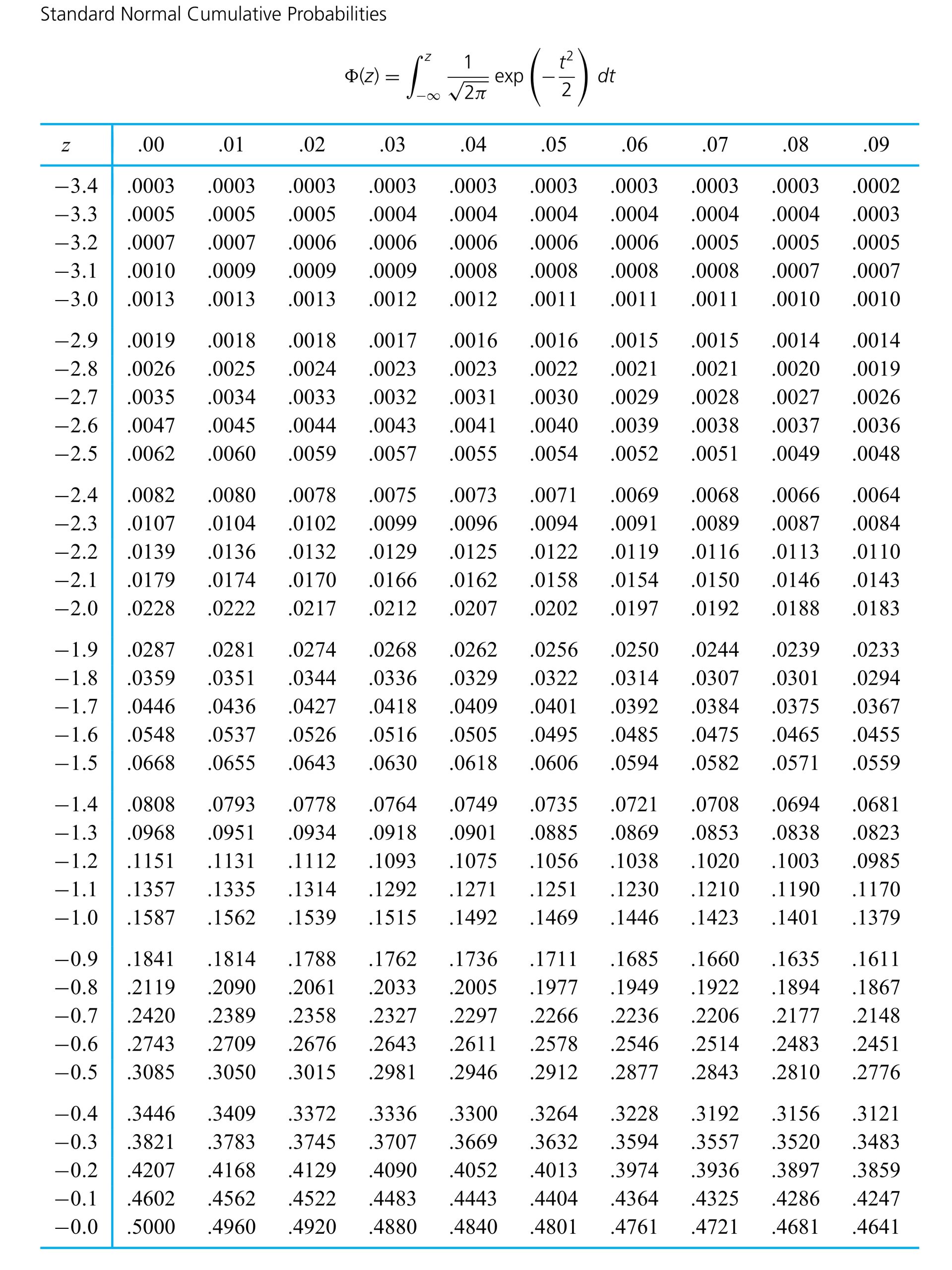

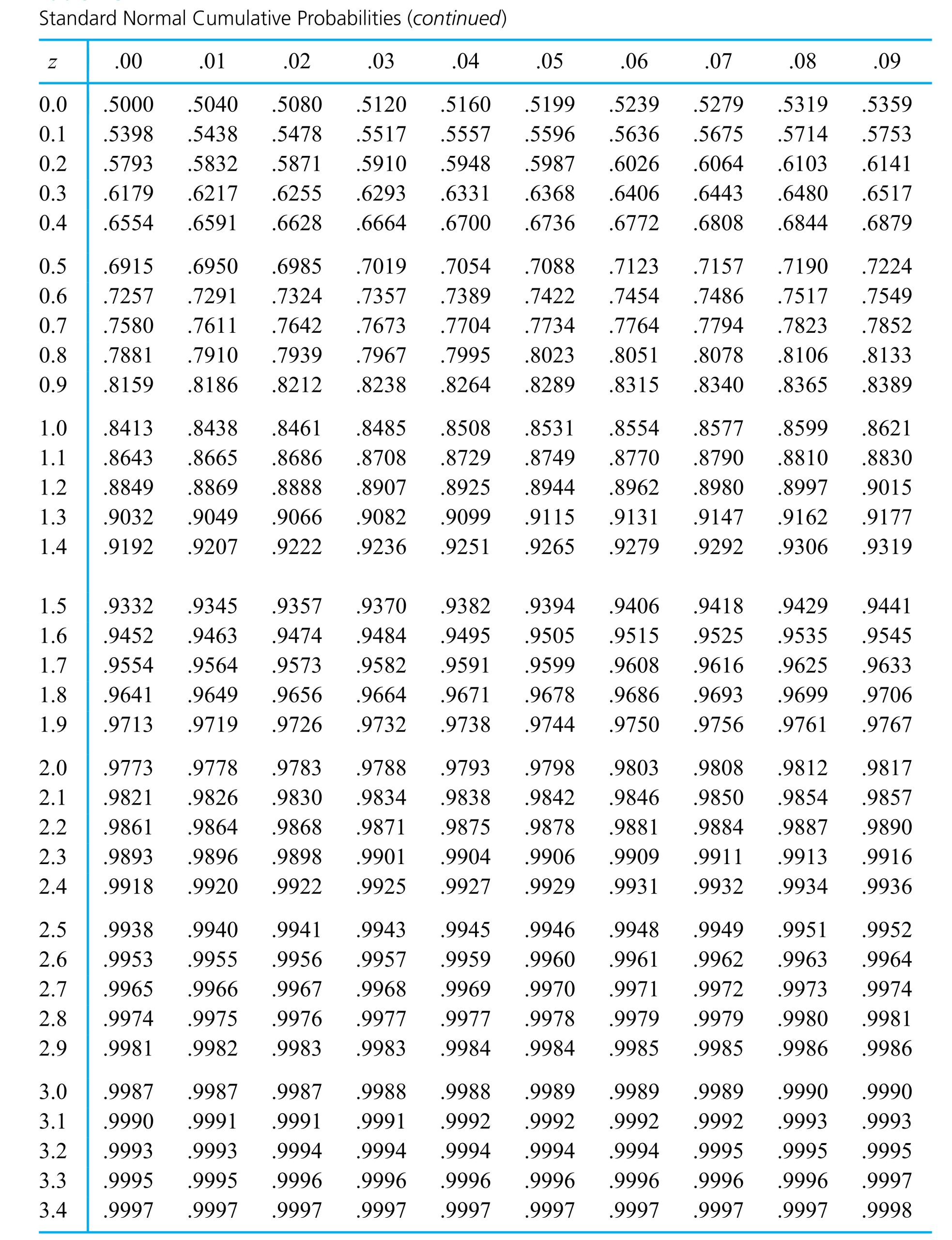

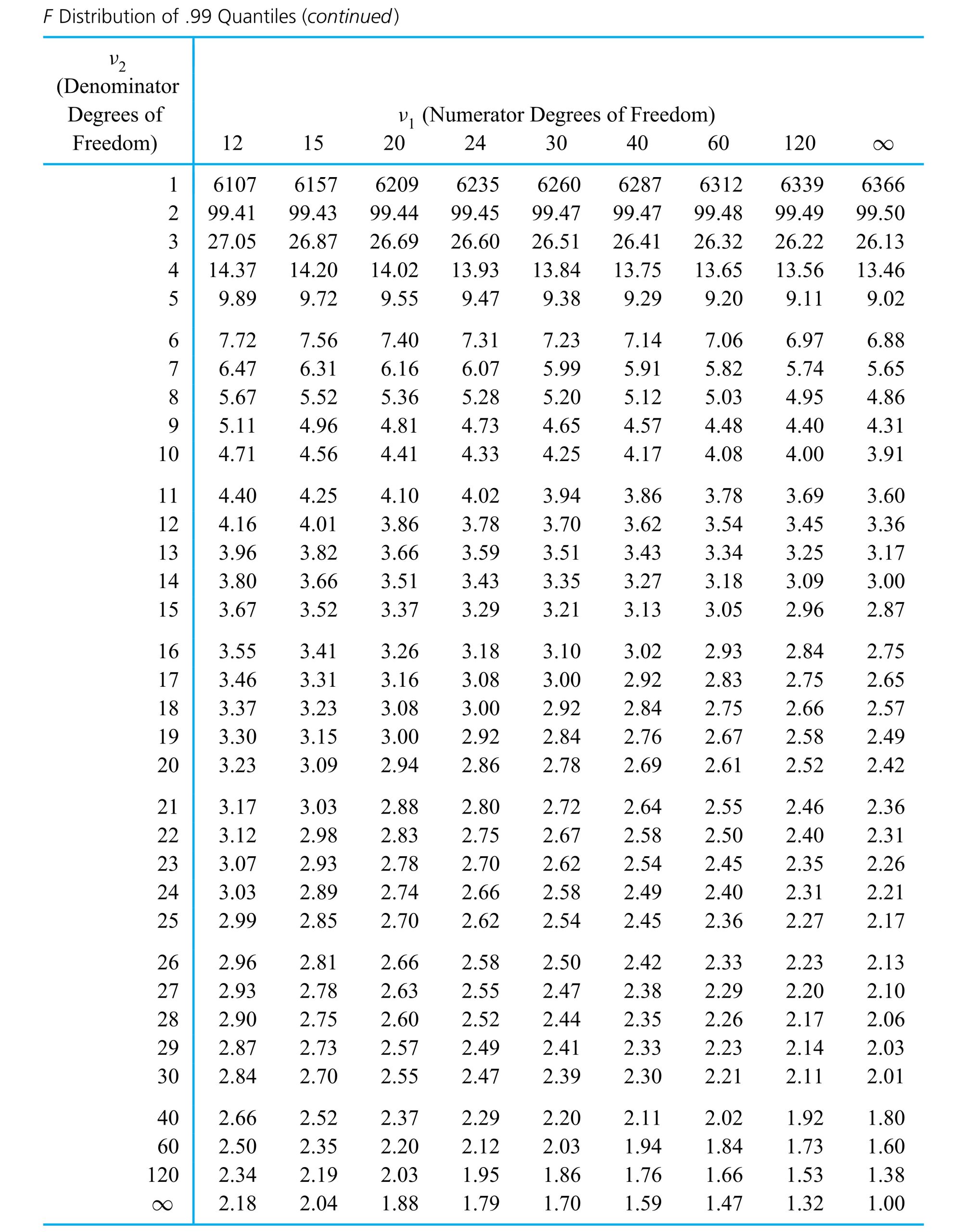

In an application, z in equation (5.1.1.6) is chosen so that the standard normal probability between −z and z corresponds to a desired confidence level. Apendix Table A1.1 (of standard normal cumulative probabilities) can be used to verify the appropriateness of the entries in Table 5.1.1.1. (This table gives values of z for use in expression (5.1.1.6) for some common confidence levels.)

Table 5.1.1.1

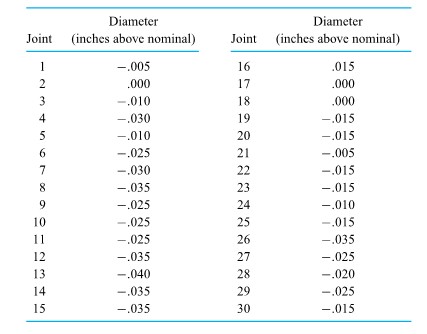

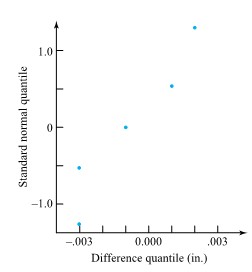

Dib, Smith, and Thompson studied a grinding process used in the rebuilding of automobile engines. The natural short-term variability associated with the diameters of rod journals on engine crankshafts ground using the process was on the order of σ = .7 × 10−4 in. Suppose that the rod journal grinding process can be thought of as physically stable over runs of, say, 50 journals or less. Then if 32 consecutive rod journal diameters have mean deviation from nominal of  =−.16 × 10−4 in., it is possible to apply expression (5.1.1.6) to make a confidence interval for the current process mean deviation from nominal. Consider a 95% confidence level. Consulting Table 5.1.1.1 (or otherwise, realizing that 1.96 is the p =.975 quantile of the standard normal distribution), z = 1.96 is called for in formula (5.1.1.6) (since .95 = 1 − 2(1 − .975)). Thus, a 95% confidence interval for the current process mean deviation from nominal journal diameter has endpoints

=−.16 × 10−4 in., it is possible to apply expression (5.1.1.6) to make a confidence interval for the current process mean deviation from nominal. Consider a 95% confidence level. Consulting Table 5.1.1.1 (or otherwise, realizing that 1.96 is the p =.975 quantile of the standard normal distribution), z = 1.96 is called for in formula (5.1.1.6) (since .95 = 1 − 2(1 − .975)). Thus, a 95% confidence interval for the current process mean deviation from nominal journal diameter has endpoints

that is, endpoints

An interval like this one could be of engineering importance in determining the advisability of making an adjustment to the process aim. The interval includes both positive and negative values. So although  < 0, the information in hand doesn’t provide enough precision to tell with any certainty in which direction the grinding process should be adjusted. This, coupled with the fact that potential machine adjustments are probably much coarser than the best-guess misadjustment of

< 0, the information in hand doesn’t provide enough precision to tell with any certainty in which direction the grinding process should be adjusted. This, coupled with the fact that potential machine adjustments are probably much coarser than the best-guess misadjustment of  =−.16 × 10−4 in., speaks strongly against making a change in the process aim based on the current data.

=−.16 × 10−4 in., speaks strongly against making a change in the process aim based on the current data.

A Generally Applicable Large-n Confidence Interval for

Although expression (5.1.1.6) provides a mathematically correct confidence interval, the appearance of σ in the formula severely limits its practical usefulness. It is unusual to have to estimate a mean µ when the corresponding σ is known (and can therefore be plugged into a formula). These situations occur primarily in manufacturing situations like those of Examples 5.1.1.1 and 2. Considerable past experience can sometimes give a sensible value for σ , while physical process drifts over time can put the current value of µ in question.

Happily, modification of the line of reasoning that led to expression (5.1.1.1) produces a confidence interval formula for µ that depends only on the characteristics of a sample. The argument leading to formula (5.1.1.6) depends on the fact that for large n,  is approximately normal with mean µ and standard deviation σ/√n—i.e., that

is approximately normal with mean µ and standard deviation σ/√n—i.e., that

5.1.1.7

is approximately standard normal. The appearance of σ in expression (5.1.1.7) is what leads to its appearance in the confidence interval formula (5.1.1.6). But a slight generalization of the central limit theorem guarantees that for large n,

5.1.1.8

is also approximately standard normal. And the variable (5.1.1.8) doesn’t involve σ .

Beginning with the fact that (when an iid model for observations is appropriate and n is large) the variable (5.1.1.8) is approximately standard normal, the reasoning is much as before. For a positive z,

-z <  < z

< z

is equivalent to

which in turn is equivalent to

Thus, the interval with random center  and random length 2zs/√n—i.e., with random endpoints

and random length 2zs/√n—i.e., with random endpoints

EXPRESSION 5.1.1.9 Large-Sample Confidence Levels for

can be used as an approximate confidence interval for µ. For a desired confidence, z should be chosen such that the standard normal probability between −z and z corresponds to that confidence level.

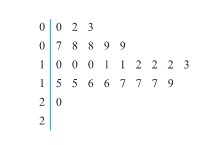

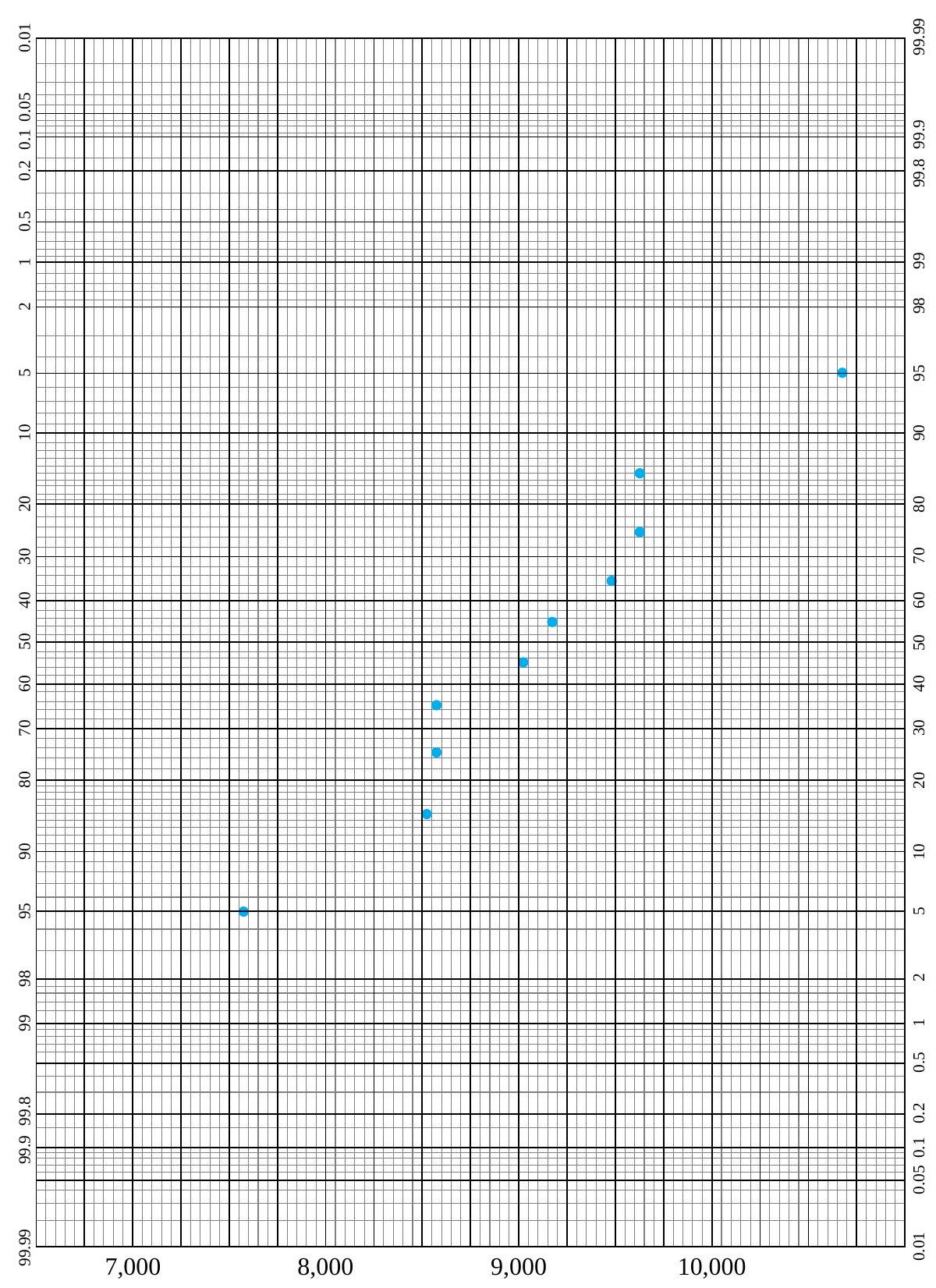

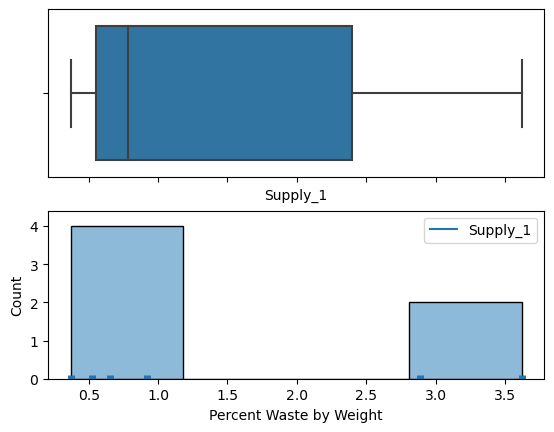

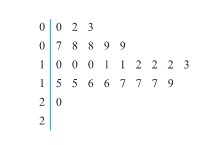

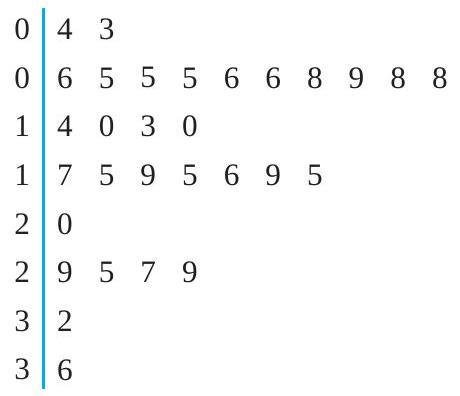

F. Willett, in the article “The Case of the Derailed Disk Drives” (Mechanical Engineering, 1988), discusses a study done to isolate the cause of “blink code A failure” in a model of Winchester hard disk drive. Included in that article are the data given in Figure 5.1.1.2. These are breakaway torques (units are inch ounces) required to loosen the drive’s interrupter flag on the stepper motor shaft for 26 disk drives returned to the manufacturer for blink code A failure. For these data,  = 11.5 in. oz and s = 5.1 in. oz.

= 11.5 in. oz and s = 5.1 in. oz.

If the disk drives that produced the data in Figure 5.1.1.2 are thought of as representing the population of drives subject to blink code A failure, it seems reasonable to use an iid model and formula (5.1.1.9) to estimate the population mean breakaway torque. Choosing to make a 90% confidence interval for µ, z = 1.645

is indicated in Table 5.1.1.1. And using formula (5.1.1.9), endpoints

(i.e., endpoints 9.9 in. oz and 13.1 in. oz) are indicated.

The interval shows that the mean breakaway torque for drives with blink code A failure was substantially below the factory’s 33.5 in. oz target value. Recognizing this turned out to be key in finding and eliminating a design flaw in the drives.

Figure 5.1.1.2 Torques required to loosen 26 interrupter flags

C: Some Comments Concerning Confidence Intervals

Formulas (5.1.1.6) and (5.1.1.9) have been used to make confidence statements of the type “µ is between a and b.” But often a statement like “µ is at least c”or“µ is no more than d ” would be of more practical value. For example, an automotive engineer might wish to state, “The mean NO emission for this engine is at most 5 ppm.” Or a civil engineer might want to make a statement like “the mean compressive strength for specimens of this type of concrete is at least 4188 psi.” That is, practical engineering problems are sometimes best addressed using one-sided confidence intervals.

Making one-sided confidence intervalsThere is no real problem in coming up with formulas for one-sided confidence intervals. If you have a workable two-sided formula, all that must be done is to

1. replace the lower limit with −∞ or the upper limit with +∞ and

2. adjust the stated confidence level appropriately upward (this usually means

dividing the “unconfidence level” by 2).

This prescription works not only with formulas (5.1.1.6) and (5.1.1.9) but also with the rest of the two-sided confidence intervals introduced in this chapter.

For the mean breakaway torque for defective disk drives, consider making a one-sided 90% confidence interval for µ of the form (−∞, #), for # an appropriate number. Put slightly differently, consider finding a 90% upper confidence bound for µ,(say,#).’

Beginning with a two-sided 80% confidence interval for µ, the lower limit canbe replaced with −∞ and a one-sided 90% confidence interval determined. Thatis, using formula (6.9), a 90% upper confidence bound for the mean breakaway torque is

Equivalently, a 90% one-sided confidence interval for µ is (−∞, 12.8).

The 12.8 in. oz figure here is less than (and closer to the sample mean than) the 13.1 in. oz upper limit from the 90% two-sided interval found earlier. In the one-sided case, −∞ is declared as a lower limit so there is no risk of producing an interval containing only numbers larger than the unknown µ. Thus an upper limit smaller than that for a corresponding two-sided interval can be used.

Interpreting a confidence interval

A second issue in the application of confidence intervals is a correct understanding of the technical meaning of the term confidence. Unfortunately, there are many possible misunderstandings. So it is important to carefully lay out what confidence

does and doesn’t mean.

Prior to selecting a sample and plugging into a formula like (5.1.1.6) or (5.1.1.9), the meaning of a confidence level is obvious. Choosing a (two-sided) 90% confidence level and thus z = 1.645 for use in formula (5.1.1.9), before the fact of sample selection and calculation, “there is about a 90% chance of winding up with an interval that brackets µ.” In symbols, this might be expressed as

![P\left[\bar{x}-1.645 \frac{s}{\sqrt{n}}<\mu<\bar{x}+1.645 \frac{s}{\sqrt{n}}\right] \approx .90 P\left[\bar{x}-1.645 \frac{s}{\sqrt{n}}<\mu<\bar{x}+1.645 \frac{s}{\sqrt{n}}\right] \approx .90](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5Cleft%5B%5Cbar%7Bx%7D-1.645%20%5Cfrac%7Bs%7D%7B%5Csqrt%7Bn%7D%7D%3C%5Cmu%3C%5Cbar%7Bx%7D%2B1.645%20%5Cfrac%7Bs%7D%7B%5Csqrt%7Bn%7D%7D%5Cright%5D%20%5Capprox%20.90&fg=000000&font=TeX&svg=1)

But how to think about a confidence level after sample selection? This is an entirely different matter. Once numbers have been plugged into a formula like (5.1.1.6) or (5.1.1.9), the die has already been cast, and the numerical interval is either right or wrong. The practical difficulty is that while which is the case can’t be determined, it no longer makes logical sense to attach a probability to the correctness of the interval. For example, it would make no sense to look again at the two-sided interval found in Example 5.1.1.3 and try to say something like “there is a 90% probability that µ is between 9.9 in. oz and 13.1 in. oz.” µ is not a random variable. It is a fixed (although unknown) quantity that either is or is not between 9.9 and 13.1. There is no probability left in the situation to be discussed.

So what does it mean that (9.9, 13.1) is a 90% confidence interval for µ? Like it or not, the phrase “90% confidence” refers more to the method used to obtain the interval (9.9, 13.1) than to the interval itself. In coming up with the interval, methodology has been used that would produce numerical intervals bracketing µ in about 90% of repeated applications. But the effectiveness of the particular interval in this application is unknown, and it is not quantifiable in terms of a probability. A person who (in the course of a lifetime) makes many 90% confidence intervals can expect to have a “lifetime success rate” of about 90%. But the effectiveness of any particular application will typically be unknown.

A short statement summarizing this discussion as “the interpretation of confidence” will be useful.

DEFINITION 5.1.1.2 Interpretation of a Confidence Interval

To say that a numerical interval (a, b) is (for example) a 90% confidence interval for a parameter is to say that in obtaining it, one has applied methods of data collection and calculation that would produce intervals bracketing the parameter in about 90% of repeated applications. Whether or not the particular interval (a, b) brackets the parameter is unknown and not describable in terms of a probability.

The reader may feel that the statement in Definition 5.1.1.2 is a rather weak meaning for the reliability figure associated with a confidence interval. Nevertheless, the statement in Definition 5.1.1.2 is the correct interpretation and is all that can be rationally expected. And despite the fact that the correct interpretation may initially seem somewhat unappealing, confidence interval methods have proved themselves to be of great practical use.

D: Sample Sizes for estimating

As a final consideration in this introduction to confidence intervals, note that formulas like (5.1.1.6) and (5.1.1.9) can give some crude quantitative answers to the question, “How big must n be?” Using formula (5.1.1.9), for example, if you have in mind (1) a desired confidence level, (2) a worst-case expectation for the sample standard deviation, and (3) a desired precision of estimation for µ, it is a simple matter to solve for a corresponding sample size. That is, suppose that the desired confidence level dictates the use of the value z in formula (5.1.1.9), s is some likely worst-case value for the sample standard deviation, and you want to have confidence limits (or a limit) of the form  ±

±  . Setting

. Setting

and solving for n produces the requirement

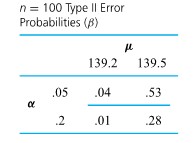

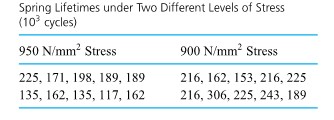

Suppose that in the disk drive problem, engineers plan to follow up the analysis of the data in Figure 5.1.1.2 with the testing of a number of new drives. This will be done after subjecting them to accelerated (high) temperature conditions, in an effort to understand the mechanism behind the creation of low breakaway torques. Further suppose that the mean breakaway torque for temperature-stressed drives is to be estimated with a two-sided 95% confidence interval and that the torque variability expected in the new temperature-stressed drives is no worse than the s = 5.1 in. oz figure obtained from the returned drives. A ±1 in. oz precision of estimation is desired. Then using the plus-or-minus part of formula (5.1.1.9) and remembering Table 5.1.1.1, the requirement is

which, when solved for n, gives

A study involving in the neighborhood of n = 100 temperature-stressed new disk drives is indicated. If this figure is impractical, the calculations at least indicate that dropping below this sample size will (unless the variability associated with the stressed new drives is less than that of the returned drives) force a reduction in either the confidence or the precision associated with the final interval.

For two reasons, the kind of calculations in the previous example give somewhat less than an ironclad answer to the question of sample size. The first is that they are only as good as the prediction of the sample standard deviation, s. If s is underpredicted, an n that is not really large enough will result. (By the same token, if one is excessively conservative and overpredicts s, an unnecessarily large sample size will result.) The second issue is that expression (5.1.1.9) remains a large-sample formula. If calculations like the preceding ones produce n smaller than, say, 25 or 30, the value should be increased enough to guarantee that formula (5.1.1.9) can be applied.

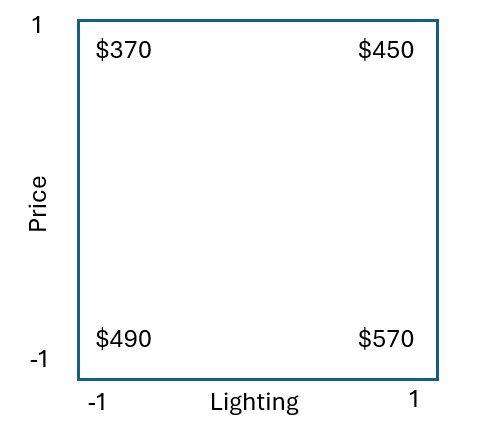

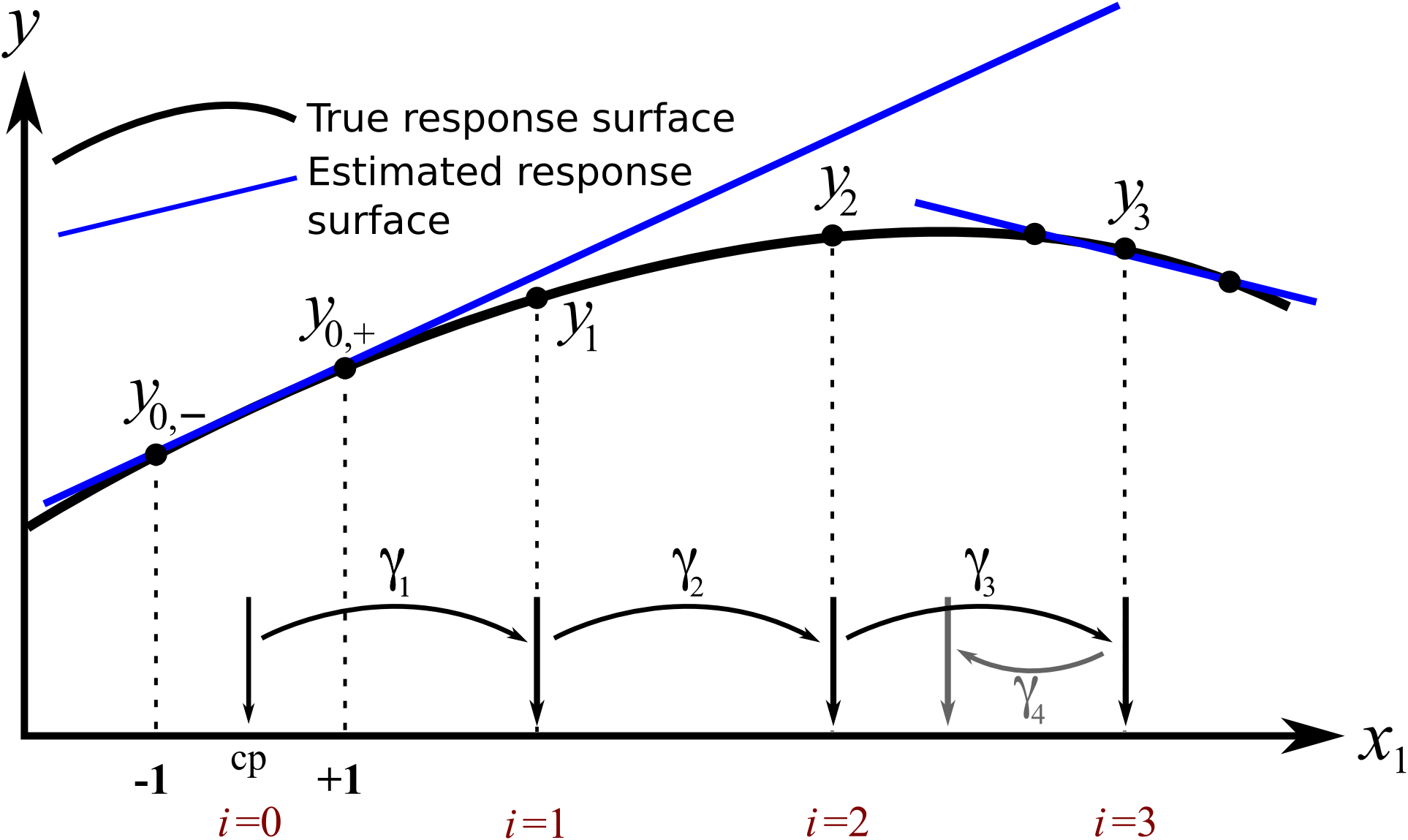

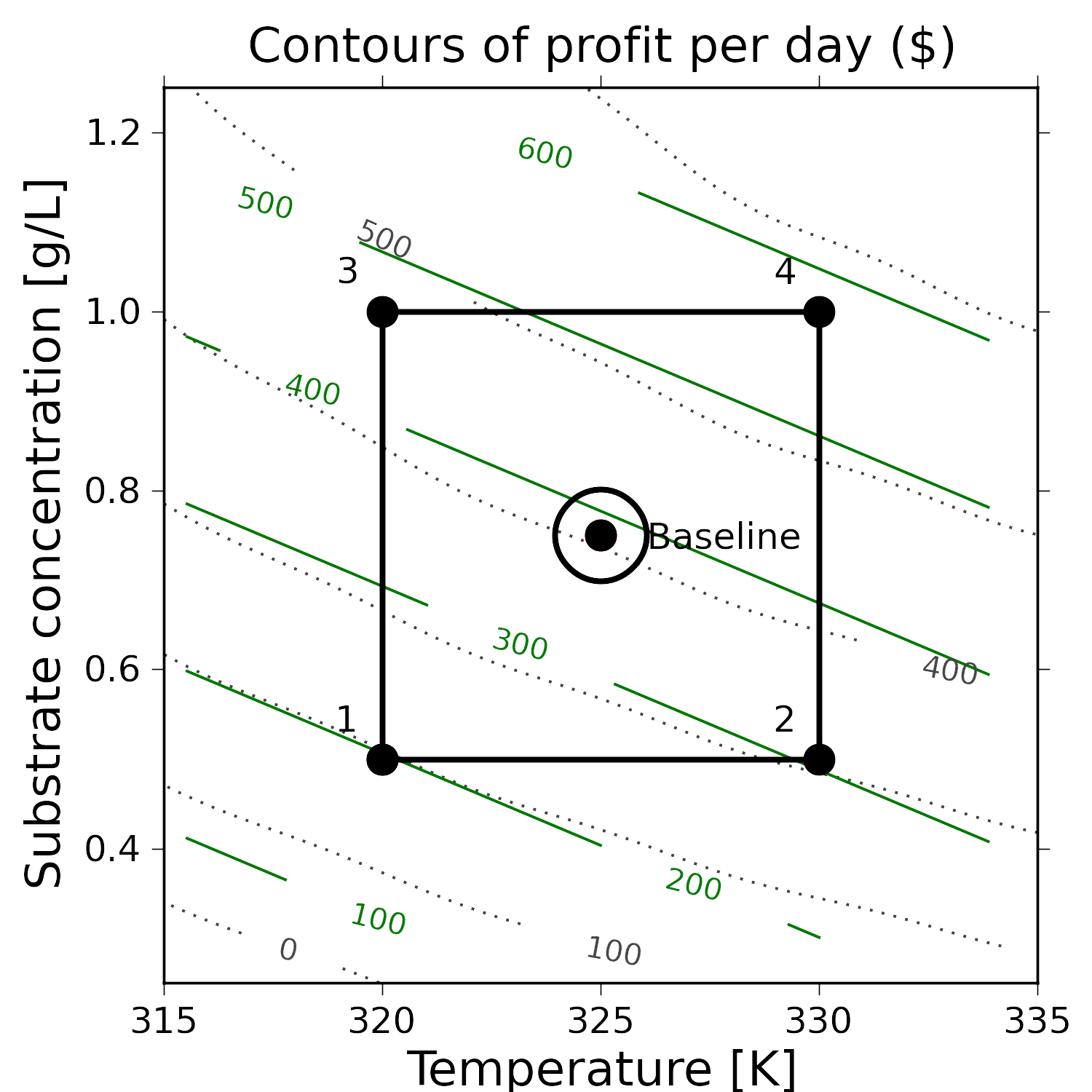

![</span>\begin{split}\hat{y} &= b_0 + b_T x_T + b_S x_S + b_{TS} x_T x_S \\ \hat{y} &= 389.8 + 55 x_T + 134 x_S - 3.50 x_T x_S\end{split}</div> where <span class="math notranslate nohighlight">[latex]x_T = \dfrac{x_{T,\text{actual}} - \text{center}_T}{\Delta_T/2} </span>\begin{split}\hat{y} &= b_0 + b_T x_T + b_S x_S + b_{TS} x_T x_S \\ \hat{y} &= 389.8 + 55 x_T + 134 x_S - 3.50 x_T x_S\end{split}</div> where <span class="math notranslate nohighlight">[latex]x_T = \dfrac{x_{T,\text{actual}} - \text{center}_T}{\Delta_T/2}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%3C%2Fspan%3E%5Cbegin%7Bsplit%7D%5Chat%7By%7D%20%26%3D%20b_0%20%2B%20b_T%20x_T%20%2B%20b_S%20x_S%20%2B%20b_%7BTS%7D%20x_T%20x_S%20%5C%5C%20%20%5Chat%7By%7D%20%26%3D%20389.8%20%2B%2055%20x_T%20%2B%20134%20x_S%20-%203.50%20x_T%20x_S%5Cend%7Bsplit%7D%3C%2Fdiv%3E%20%20where%20%3Cspan%20class%3D%22math%20notranslate%20nohighlight%22%3E%5Blatex%5Dx_T%20%3D%20%5Cdfrac%7Bx_%7BT%2C%5Ctext%7Bactual%7D%7D%20-%20%5Ctext%7Bcenter%7D_T%7D%7B%5CDelta_T%2F2%7D&fg=000000&font=TeX&svg=1)

=

=

in free fall an object will have velocity

in free fall an object will have velocity =

=

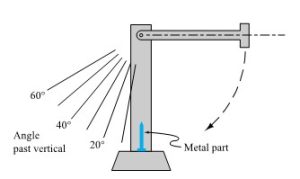

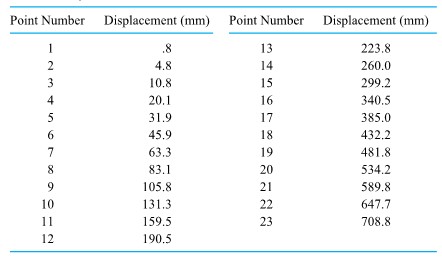

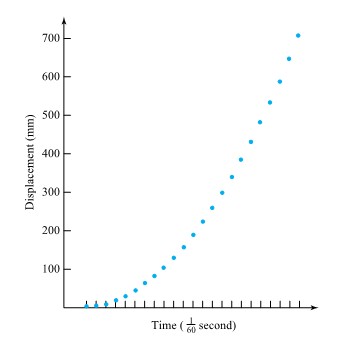

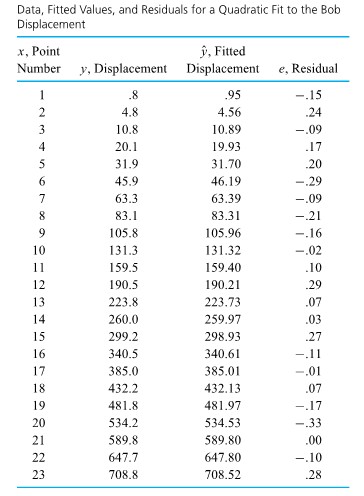

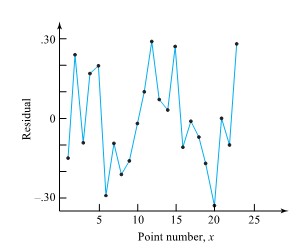

of a second. Table 1.1.7.1 gives measurements of such positions. (Dr. Frank Peterson of the ISU Physics and Astronomy Department supplied the tape.) Plotting the bob positions in the table at equally spaced intervals produces the approximately quadratic plot shown in Figure 1.1.7.2. Picking a parabola to fit the plotted points involves identifying an appropriate value for

of a second. Table 1.1.7.1 gives measurements of such positions. (Dr. Frank Peterson of the ISU Physics and Astronomy Department supplied the tape.) Plotting the bob positions in the table at equally spaced intervals produces the approximately quadratic plot shown in Figure 1.1.7.2. Picking a parabola to fit the plotted points involves identifying an appropriate value for  /

/ , not far from the commonly quoted value of 9.8

, not far from the commonly quoted value of 9.8

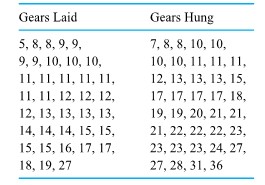

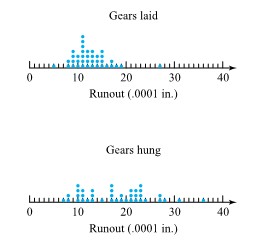

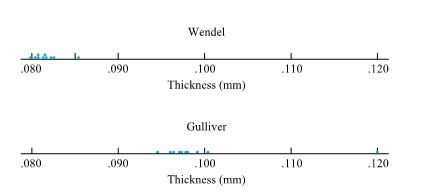

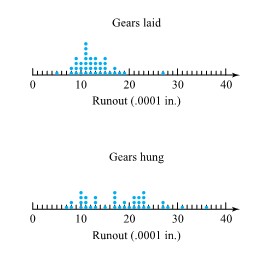

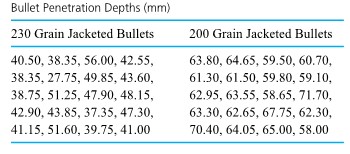

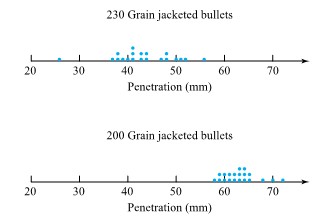

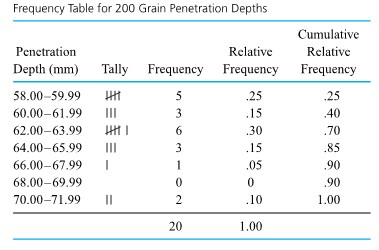

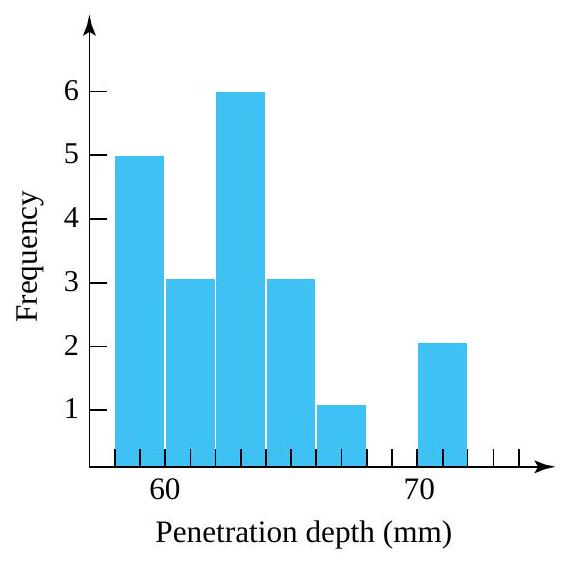

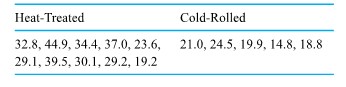

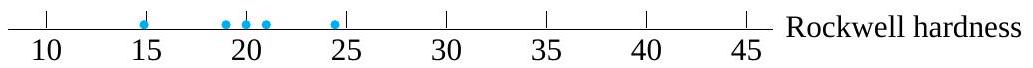

from the target surface to the back of the bullets) for two bullet types. Figure 2.2.2.2 presents a corresponding pair of dot diagrams.

from the target surface to the back of the bullets) for two bullet types. Figure 2.2.2.2 presents a corresponding pair of dot diagrams.

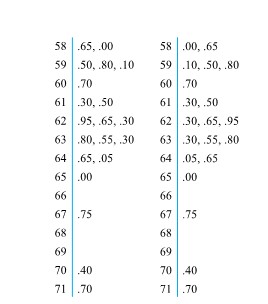

” and ”

” and ”  ” leaf positions for each possible leading digit, instead of only a single ”

” leaf positions for each possible leading digit, instead of only a single ”  ” leaf for each leading digit.

” leaf for each leading digit.

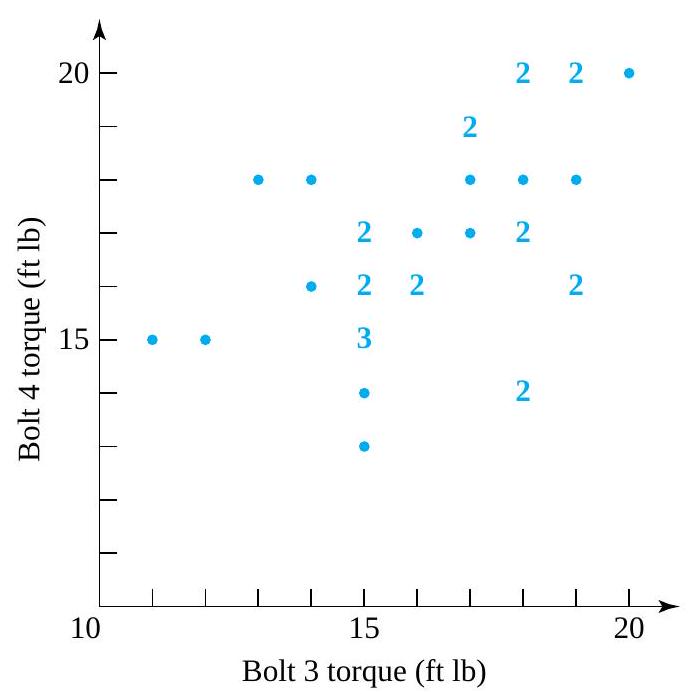

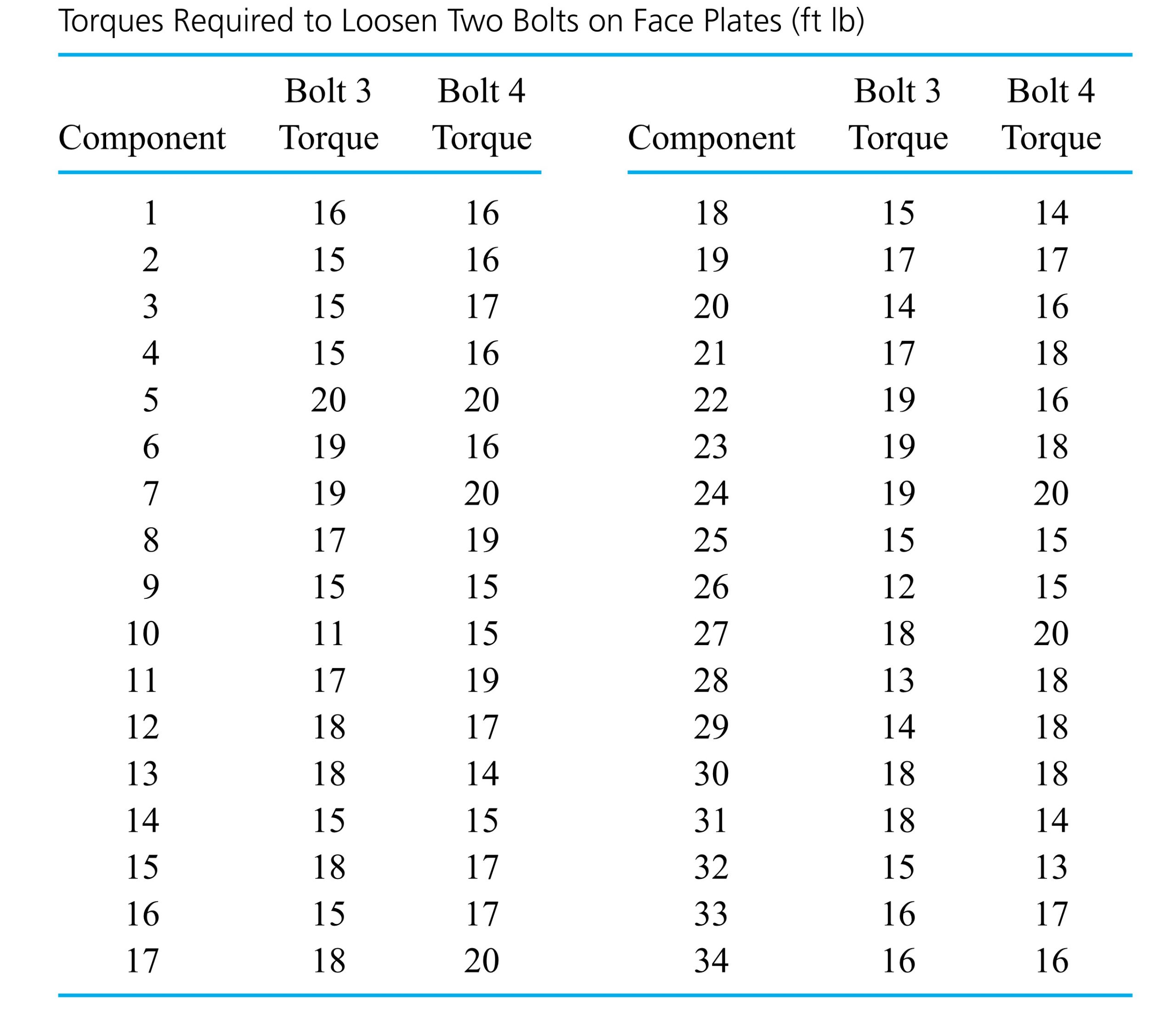

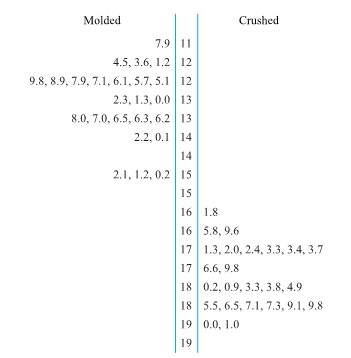

required for bolts number 3 and 4), respectively, on 34 different components. Figure 2.1.4.1 is a scatterplot of the bivariate data from Table 2.1.4.1. In this figure, where several points must be plotted at a single location, the number of points occupying the location has been plotted instead of a single dot.

required for bolts number 3 and 4), respectively, on 34 different components. Figure 2.1.4.1 is a scatterplot of the bivariate data from Table 2.1.4.1. In this figure, where several points must be plotted at a single location, the number of points occupying the location has been plotted instead of a single dot.

of those taking the test had worse scores, and roughly

of those taking the test had worse scores, and roughly  had better scores. This concept is also useful in the description of engineering data. However, because it is often more convenient to work in terms of fractions between 0 and 1 rather than in percentages between 0 and 100, slightly different terminology will be used here: “Quantiles,” rather than percentiles, will be discussed. After the quantiles of a data set are carefully defined, they are used to create a number of useful tools of descriptive statistics: quantile plots, boxplots,

had better scores. This concept is also useful in the description of engineering data. However, because it is often more convenient to work in terms of fractions between 0 and 1 rather than in percentages between 0 and 100, slightly different terminology will be used here: “Quantiles,” rather than percentiles, will be discussed. After the quantiles of a data set are carefully defined, they are used to create a number of useful tools of descriptive statistics: quantile plots, boxplots,  plots, and normal plots (a type of theoretical

plots, and normal plots (a type of theoretical  between 0 and 1 , the

between 0 and 1 , the  of the distribution lies to the right. However, because of the discreteness of finite data sets, it is necessary to state exactly what will be meant by the terminology. Definition 1 gives the precise convention that will be used in this text.

of the distribution lies to the right. However, because of the discreteness of finite data sets, it is necessary to state exactly what will be meant by the terminology. Definition 1 gives the precise convention that will be used in this text. values that when ordered are

values that when ordered are  ,

, for a positive integer

for a positive integer  , the

, the

quantile.)

quantile.) and

and  that is not of the form

that is not of the form  , the

, the  with corresponding

with corresponding  will be used to denote the

will be used to denote the  and

and  . To find

. To find  for

for

th ordered data point.”

th ordered data point.” , one can easily find the

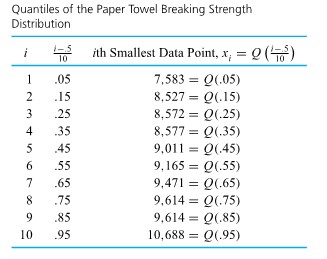

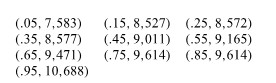

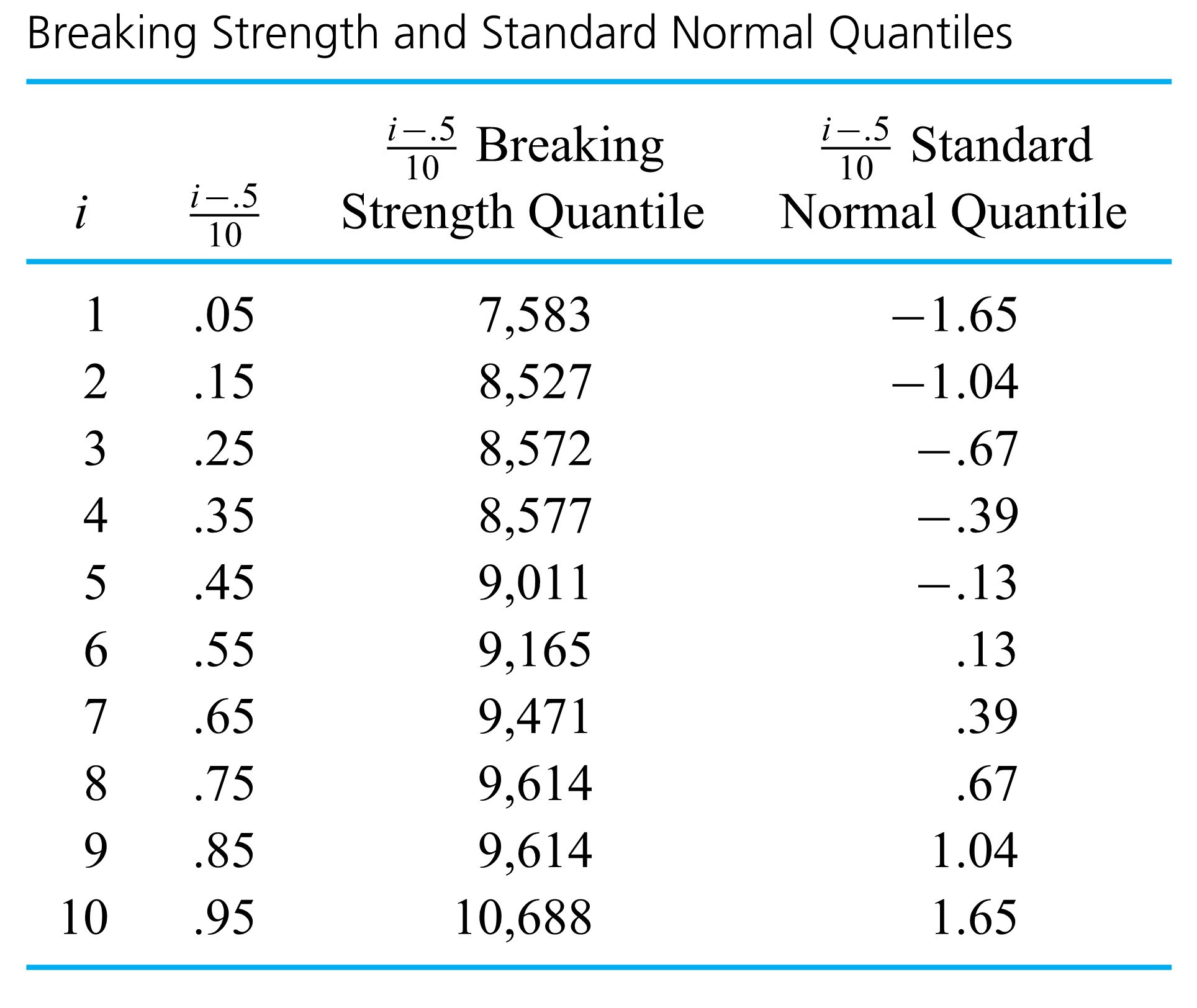

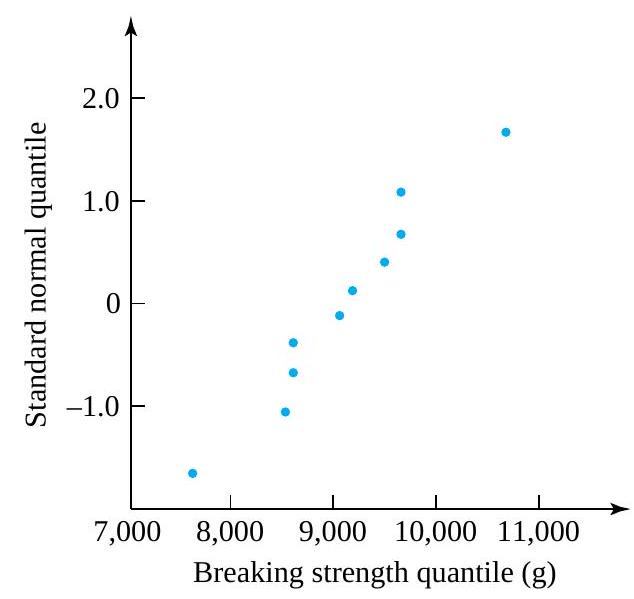

, one can easily find the  , and .95 quantiles of the breaking strength distribution, as shown in Table 31.5.2.

, and .95 quantiles of the breaking strength distribution, as shown in Table 31.5.2.

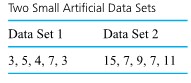

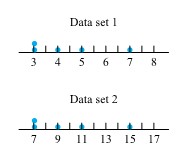

data points, each one accounts for

data points, each one accounts for  of the data set. Applying convention (1) in Definition 3.1.5.1 to find (for example) the .35 quantile, the smallest 3 data points and half of the fourth smallest are counted as lying to (continued) the left of the desired number, and the largest 6 data points and half of the seventh largest are counted as lying to the right. Thus, the fourth smallest data point must be the .35 quantile, as is shown in Table 2.1.5.2.

of the data set. Applying convention (1) in Definition 3.1.5.1 to find (for example) the .35 quantile, the smallest 3 data points and half of the fourth smallest are counted as lying to (continued) the left of the desired number, and the largest 6 data points and half of the seventh largest are counted as lying to the right. Thus, the fourth smallest data point must be the .35 quantile, as is shown in Table 2.1.5.2. of the way from .45 to .55 , linear interpolation gives:

of the way from .45 to .55 , linear interpolation gives:

of the way from .85 to .95 , linear interpolation gives:

of the way from .85 to .95 , linear interpolation gives:

is called the median of a distribution.

is called the median of a distribution. and

and  are called the first (or lower) quartile and third (or upper) quartile of a distribution, respectively.

are called the first (or lower) quartile and third (or upper) quartile of a distribution, respectively. previously computed, for the (continued) breaking strength distribution

previously computed, for the (continued) breaking strength distribution

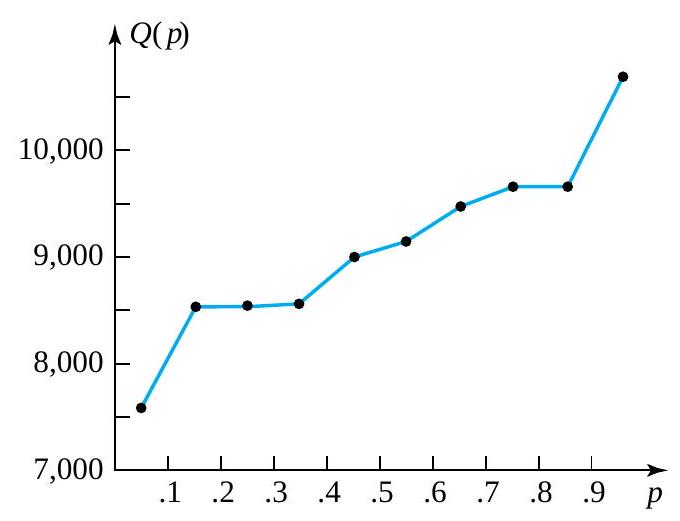

and then connecting consecutive plotted points with straight-line segments.

and then connecting consecutive plotted points with straight-line segments.

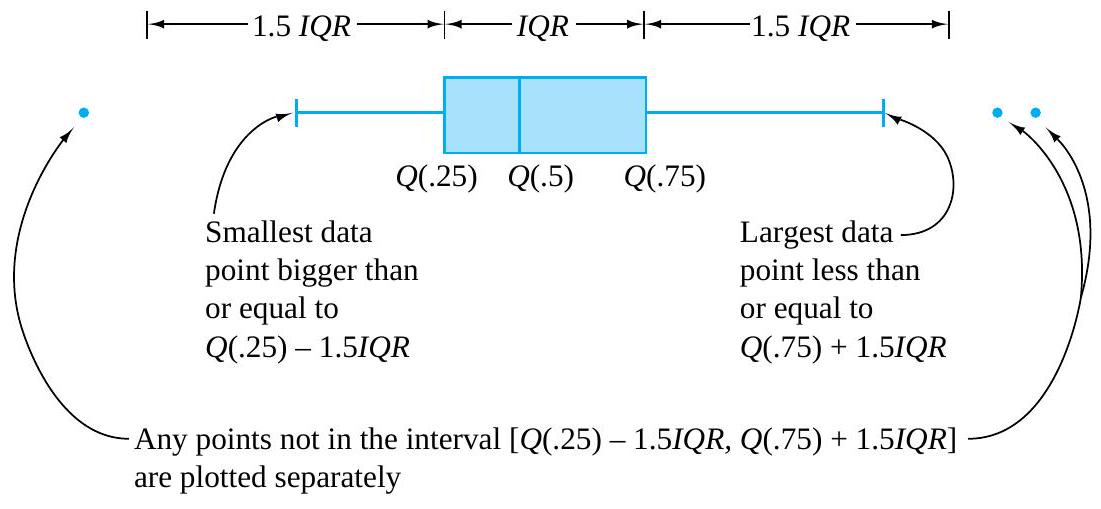

and the largest data point within 1.5IQR of

and the largest data point within 1.5IQR of ![[Q(.25)-1.5 I Q R, Q(.75)+1.5 I Q R] [Q(.25)-1.5 I Q R, Q(.75)+1.5 I Q R]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5BQ%28.25%29-1.5%20I%20Q%20R%2C%20Q%28.75%29%2B1.5%20I%20Q%20R%5D&fg=000000&font=TeX&svg=1) . Any that are not then get plotted individually and are thereby identified as outlying or unusual.

. Any that are not then get plotted individually and are thereby identified as outlying or unusual.

to

to  , the boxplot is as shown in Figure 2.1.6.2.

, the boxplot is as shown in Figure 2.1.6.2.

of the distribution. Some elements of distributional shape are indicated by the symmetry (or lack thereof) of the box and of the whiskers. And a gap between the end of a whisker and a separately plotted point serves as a reminder that no data values fall in that interval.

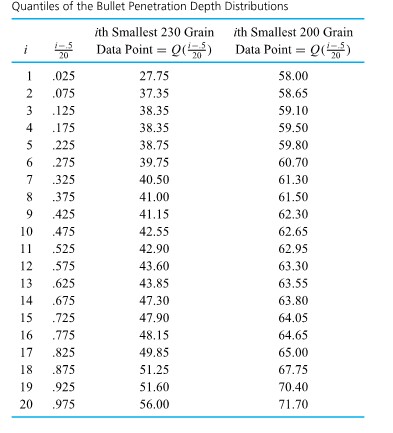

of the distribution. Some elements of distributional shape are indicated by the symmetry (or lack thereof) of the box and of the whiskers. And a gap between the end of a whisker and a separately plotted point serves as a reminder that no data values fall in that interval. quantiles for the two distributions of bullet penetration depth introduced in the previous section. For the 230 grain bullet penetration depths, interpolation yields

quantiles for the two distributions of bullet penetration depth introduced in the previous section. For the 230 grain bullet penetration depths, interpolation yields

plot.

plot. th smallest value in data set 1

th smallest value in data set 1

and

and  stand for the quantile functions of the two respective data sets, it is clear from display (2.1.7.1) that

stand for the quantile functions of the two respective data sets, it is clear from display (2.1.7.1) that

) should be exactly linear. Figure 3.16 illustrates this-in fact Figure 3.16 is a

) should be exactly linear. Figure 3.16 illustrates this-in fact Figure 3.16 is a  for appropriate values of

for appropriate values of  . When two data sets of unequal sizes are involved, the values of

. When two data sets of unequal sizes are involved, the values of  and

and  (for the 230 grain data) is out of proportion to the gap between 63.55 and

(for the 230 grain data) is out of proportion to the gap between 63.55 and  (for the 200 grain data). This hints that there was some kind of basic physical difference in the mechanisms that produced the smaller and larger 230 grain penetration depths. Once this kind of indication is discovered, it is a task for ballistics experts or materials people to explain the phenomenon.

(for the 200 grain data). This hints that there was some kind of basic physical difference in the mechanisms that produced the smaller and larger 230 grain penetration depths. Once this kind of indication is discovered, it is a task for ballistics experts or materials people to explain the phenomenon. , there is also a drastic difference in the shapes of the extreme lower ends of the two distributions. In order to move that point back on line with the rest of the plotted points, it would need to be moved to the right or down (i.e., increase the smallest 230 grain observation or decrease the smallest 200 grain observation). That is, relative to the 200 grain distribution, the 230 grain distribution is long-tailed to the low side. (Or to put it differently, relative to the 230 grain distribution, the 200 grain distribution is short-tailed to the low side.) Note that the difference in shapes was already evident in the boxplot in Figure previously. Again, it would remain for a specialist to explain this difference in distributional shapes.

, there is also a drastic difference in the shapes of the extreme lower ends of the two distributions. In order to move that point back on line with the rest of the plotted points, it would need to be moved to the right or down (i.e., increase the smallest 230 grain observation or decrease the smallest 200 grain observation). That is, relative to the 200 grain distribution, the 230 grain distribution is long-tailed to the low side. (Or to put it differently, relative to the 230 grain distribution, the 200 grain distribution is short-tailed to the low side.) Note that the difference in shapes was already evident in the boxplot in Figure previously. Again, it would remain for a specialist to explain this difference in distributional shapes.

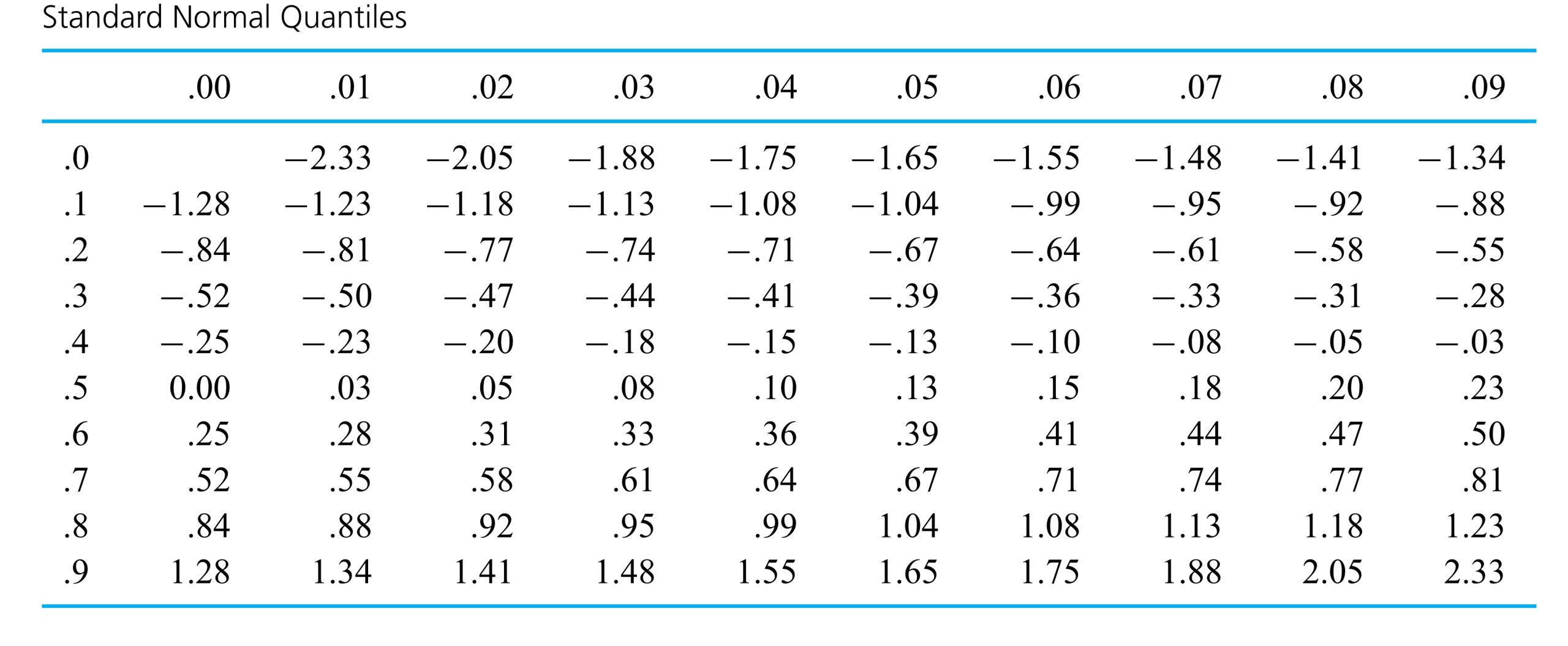

, locate the entry in the row labelled by the first digit after the decimal place and in the column labelled by the second digit after the decimal place. (For example,

, locate the entry in the row labelled by the first digit after the decimal place and in the column labelled by the second digit after the decimal place. (For example,  .) A simple numerical approximation to the values given in Table 3.10 adequate for most plotting purposes is

.) A simple numerical approximation to the values given in Table 3.10 adequate for most plotting purposes is

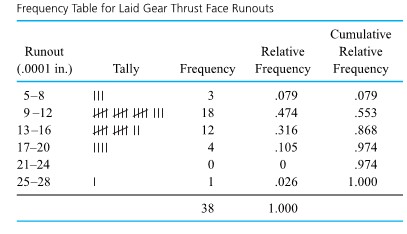

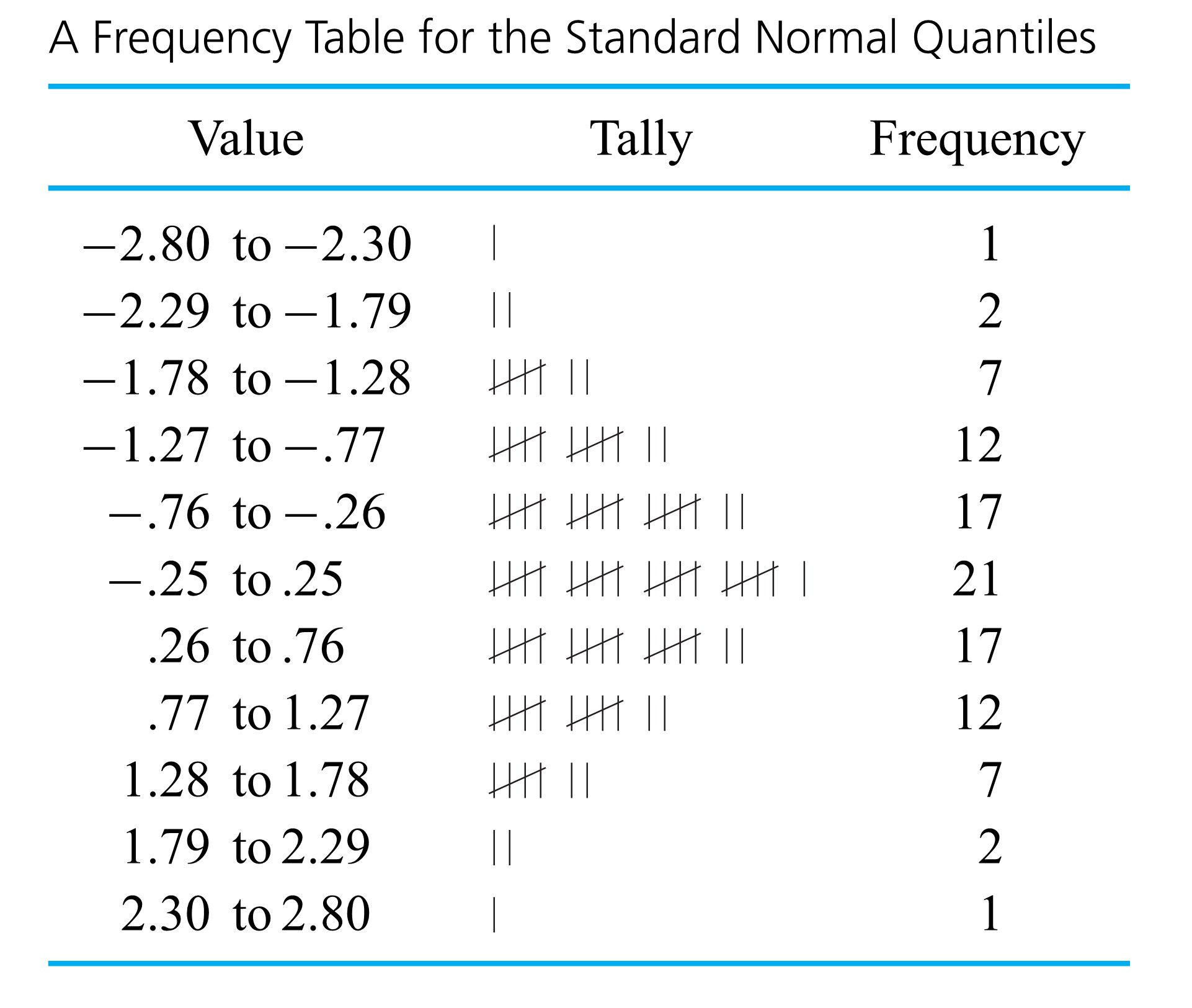

. A possible frequency table for those 99 data points is given as Table 2.1.7.3. The tally column in Table 2.1.7.3 shows clearly the bell shape.

. A possible frequency table for those 99 data points is given as Table 2.1.7.3. The tally column in Table 2.1.7.3 shows clearly the bell shape.

![Q-Q[l/atex] plotting here makes it possible to emphasize the relationship between probability plotting and (empirical) [latex]Q-Q Q-Q[l/atex] plotting here makes it possible to emphasize the relationship between probability plotting and (empirical) [latex]Q-Q](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=Q-Q%5Bl%2Fatex%5D%20plotting%20here%20makes%20it%20possible%20to%20emphasize%20the%20relationship%20between%20probability%20plotting%20and%20%28empirical%29%20%5Blatex%5DQ-Q&fg=000000&font=TeX&svg=1) plotting.

plotting.

and/or the value 2 is replaced by

and/or the value 2 is replaced by  .

. , is

, is

.

.

is

is

.” Since the range depends only on the values of the smallest and largest points in a data set, it is necessarily highly sensitive to extreme (or outlying) values. Because it is easily calculated, it has enjoyed long-standing popularity in industrial settings, particularly as a tool in statistical quality control.

.” Since the range depends only on the values of the smallest and largest points in a data set, it is necessarily highly sensitive to extreme (or outlying) values. Because it is easily calculated, it has enjoyed long-standing popularity in industrial settings, particularly as a tool in statistical quality control. is

is

, is the nonnegative square root of the sample variance.

, is the nonnegative square root of the sample variance. for

for  is an average squared distance of the data points from the central value

is an average squared distance of the data points from the central value

and

and  to stand for the population mean and to write:

to stand for the population mean and to write:

is used in place of

is used in place of  to stand for the population variance and to define:

to stand for the population variance and to define:

is then called the population standard deviation,

is then called the population standard deviation,  .

.

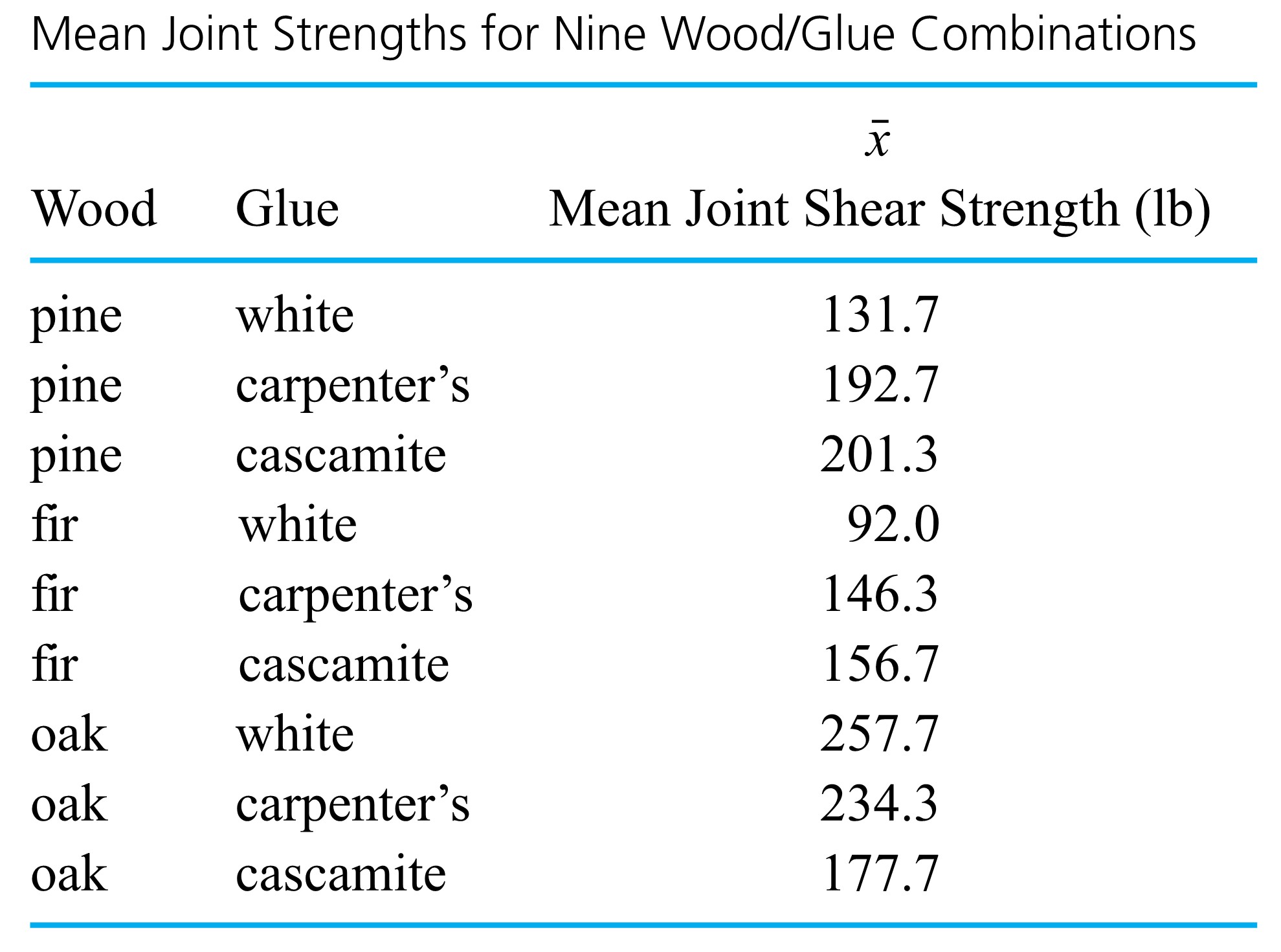

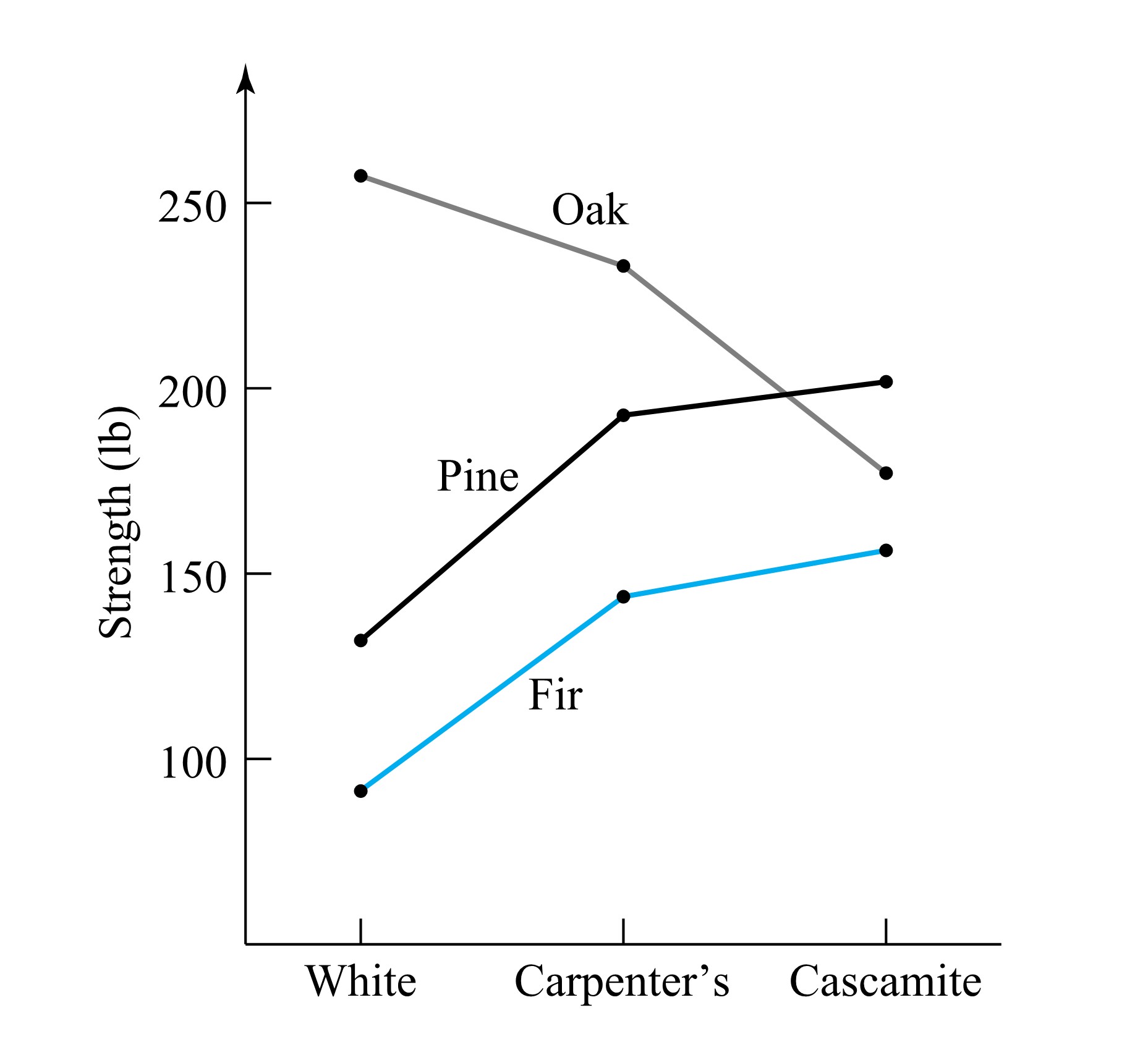

different

different

or

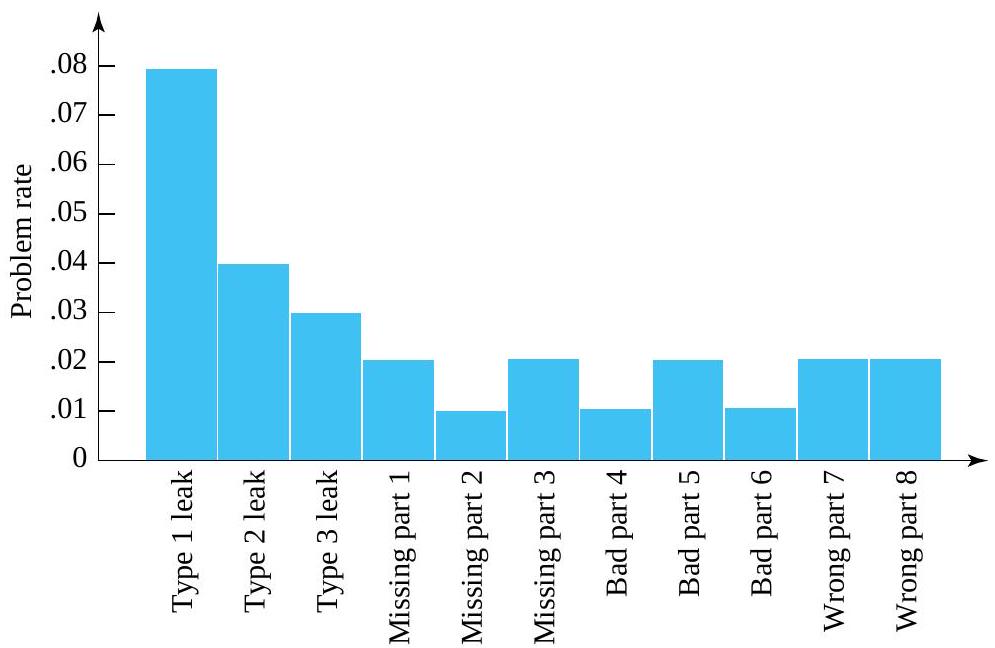

or  that need to be compared. Bar charts and simple bivariate plots can be a great aid in summarizing these results.

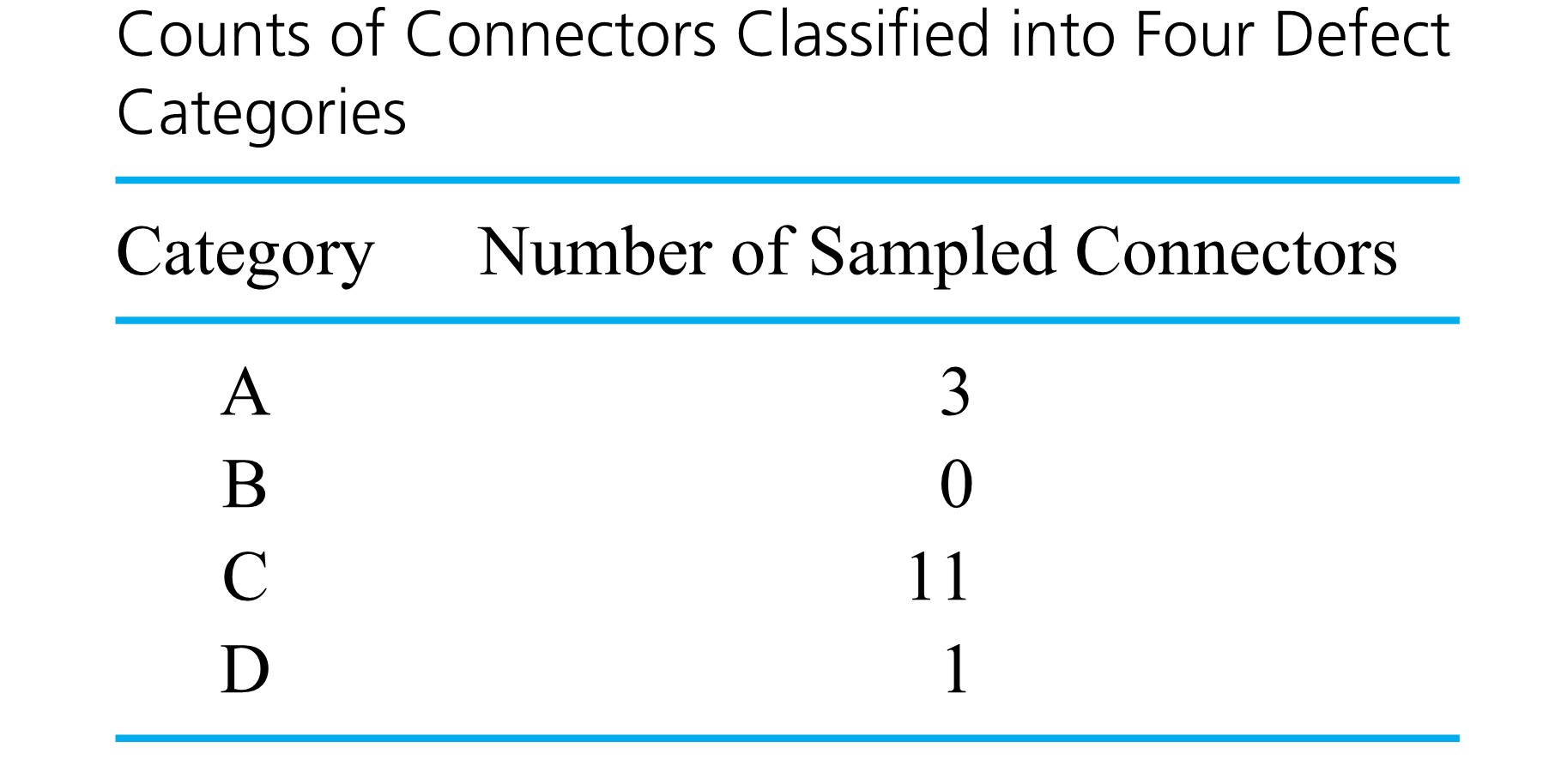

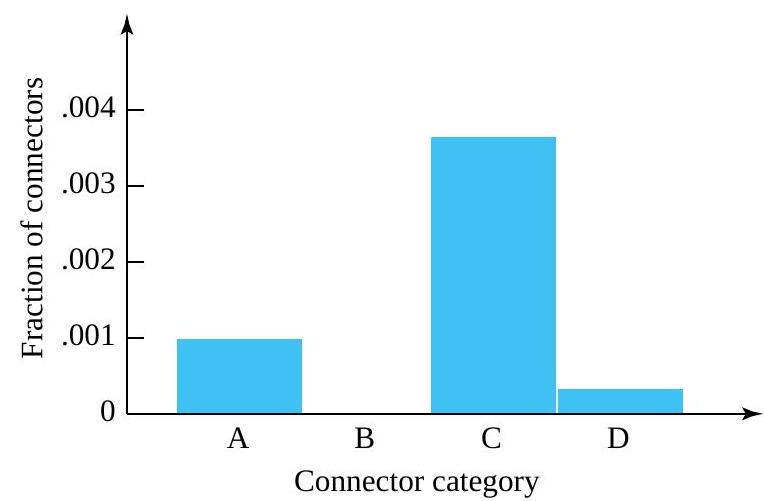

that need to be compared. Bar charts and simple bivariate plots can be a great aid in summarizing these results.![30 \times 100=3,000[latex] connectors were inspected over this period,</div> <div> <div style="text-align: center">[latex]\begin{aligned}& \hat{p}_{\mathrm{A}}=3 / 3000=.0010 \\& \hat{p}_{\mathrm{B}}=0 / 3000=.0000 \\& \hat{p}_{\mathrm{C}}=11 / 3000=.0037 \\& \hat{p}_{\mathrm{D}}=1 / 3000=.0003\end{aligned} 30 \times 100=3,000[latex] connectors were inspected over this period,</div> <div> <div style="text-align: center">[latex]\begin{aligned}& \hat{p}_{\mathrm{A}}=3 / 3000=.0010 \\& \hat{p}_{\mathrm{B}}=0 / 3000=.0000 \\& \hat{p}_{\mathrm{C}}=11 / 3000=.0037 \\& \hat{p}_{\mathrm{D}}=1 / 3000=.0003\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=30%20%5Ctimes%20100%3D3%2C000%5Blatex%5D%20connectors%20were%20inspected%20over%20this%20period%2C%3C%2Fdiv%3E%20%20%3Cdiv%3E%20%20%3Cdiv%20style%3D%22text-align%3A%20center%22%3E%5Blatex%5D%5Cbegin%7Baligned%7D%26%20%5Chat%7Bp%7D_%7B%5Cmathrm%7BA%7D%7D%3D3%20%2F%203000%3D.0010%20%5C%5C%26%20%5Chat%7Bp%7D_%7B%5Cmathrm%7BB%7D%7D%3D0%20%2F%203000%3D.0000%20%5C%5C%26%20%5Chat%7Bp%7D_%7B%5Cmathrm%7BC%7D%7D%3D11%20%2F%203000%3D.0037%20%5C%5C%26%20%5Chat%7Bp%7D_%7B%5Cmathrm%7BD%7D%7D%3D1%20%2F%203000%3D.0003%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

, because categories A through E represent a set of nonoverlapping and exhaustive classifications into which an individual connector must fall, so that the

, because categories A through E represent a set of nonoverlapping and exhaustive classifications into which an individual connector must fall, so that the

, having moderately serious defects but no serious or very serious defects. This bar chart is a presentation of the behavior of a single categorical variable.

, having moderately serious defects but no serious or very serious defects. This bar chart is a presentation of the behavior of a single categorical variable.

, so

, so  for the fraction of tools without type 1 leaks. The

for the fraction of tools without type 1 leaks. The

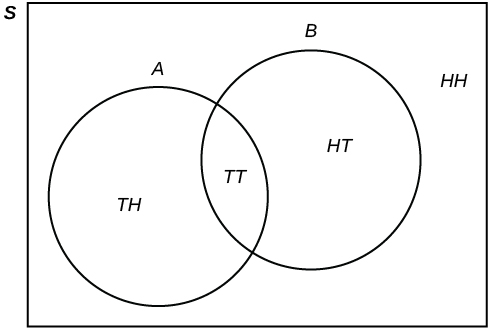

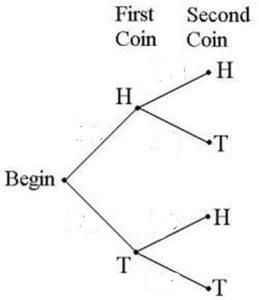

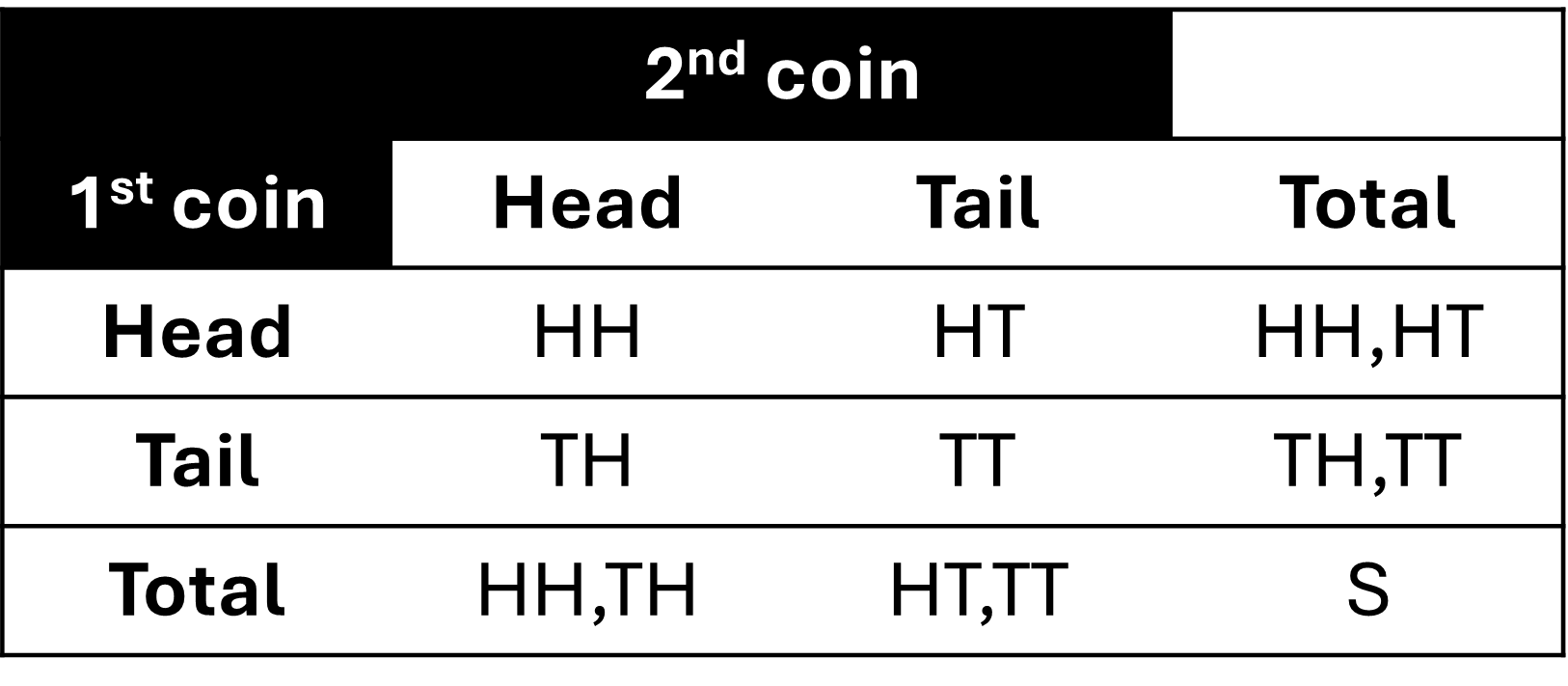

where H = heads and T = tails are the outcomes. The sample space for flipping two fair coins once is shown: S = {(HH),(HT),(TH),(TT)}. We will also use capital letters to denote an event, like A and B. For example, we can define event A as realizing tails on the first coin and event B= tails on the second coin. This would be shown as

where H = heads and T = tails are the outcomes. The sample space for flipping two fair coins once is shown: S = {(HH),(HT),(TH),(TT)}. We will also use capital letters to denote an event, like A and B. For example, we can define event A as realizing tails on the first coin and event B= tails on the second coin. This would be shown as  and

and  . Using diagrams is helpful in representing the operations of multiple events together.

. Using diagrams is helpful in representing the operations of multiple events together. is in neither

is in neither  nor

nor  . The Venn diagram is as follows:

. The Venn diagram is as follows:

. The marginal events are those shown on the margins of the table, and are those that occur for a single event with no regard for the other events in the table. For our example, we have marginal event A and the associated joint events,

. The marginal events are those shown on the margins of the table, and are those that occur for a single event with no regard for the other events in the table. For our example, we have marginal event A and the associated joint events,

.

. .

. .

. .

. is the set of outcomes that are in both

is the set of outcomes that are in both  is the set of outcomes that are in either

is the set of outcomes that are in either  . Therefore

. Therefore  is the set of outcomes that are not in

is the set of outcomes that are not in  , with m being the number of outcomes in the the event A occurs and n being the total number of outcomes of the experiment. A claim of the frequentist approach is that, as the number of trials increases, the change in the relative frequency will diminish. Hence, one can view a probability as the limiting value of the corresponding relative frequencies. You can realize the relative frequency by either running real experiments and finding an empirical or estimated probability or by recognizing the theoretical model for the experiment and adopting a theoretical probability based on events from the sample space.

, with m being the number of outcomes in the the event A occurs and n being the total number of outcomes of the experiment. A claim of the frequentist approach is that, as the number of trials increases, the change in the relative frequency will diminish. Hence, one can view a probability as the limiting value of the corresponding relative frequencies. You can realize the relative frequency by either running real experiments and finding an empirical or estimated probability or by recognizing the theoretical model for the experiment and adopting a theoretical probability based on events from the sample space.

= 0.5.

= 0.5.

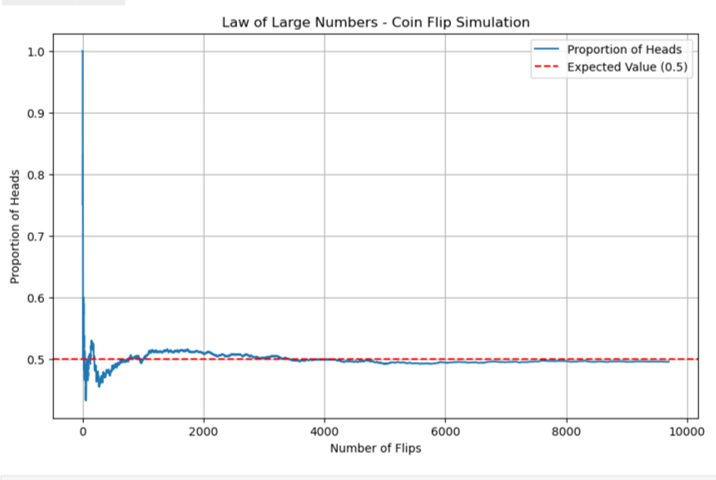

, is assigned a number between zero and one, inclusive, and describes the proportion of time we expect the event to occur over the long-term. P(A) = 0 means the event A can never happen. P(A) = 1 means the event A always happens. P(A) = 0.5 means the event A is equally likely to occur or not to occur. For example, if you flip one fair coin repeatedly (from 20 to 2,000 to 20,000 times) the relative frequency of heads approaches 0.5 (the probability of heads).

, is assigned a number between zero and one, inclusive, and describes the proportion of time we expect the event to occur over the long-term. P(A) = 0 means the event A can never happen. P(A) = 1 means the event A always happens. P(A) = 0.5 means the event A is equally likely to occur or not to occur. For example, if you flip one fair coin repeatedly (from 20 to 2,000 to 20,000 times) the relative frequency of heads approaches 0.5 (the probability of heads). is 1 and the probability of the empty set is 0. This is: P(S) = 1 and P(∅) = 0.

is 1 and the probability of the empty set is 0. This is: P(S) = 1 and P(∅) = 0.

as “the probability of A given B”.

as “the probability of A given B”. .

. .

. .

. are mutually independent if for any sub-collection

are mutually independent if for any sub-collection  there is:

there is:

cards. It consists of four suits. The suits are clubs, diamonds, hearts and spades. There are

cards. It consists of four suits. The suits are clubs, diamonds, hearts and spades. There are  cards in each suit consisting of

cards in each suit consisting of  ,

,  (jack),

(jack),  (queen),

(queen),  (king) of that suit.

(king) of that suit. cards remaining in the deck. It is the three of diamonds. You put this card aside and pick the third card from the remaining

cards remaining in the deck. It is the three of diamonds. You put this card aside and pick the third card from the remaining  cards in the deck. The third card is the

cards in the deck. The third card is the

![{\displaystyle [0,1]\subseteq \mathbb {R} } {\displaystyle [0,1]\subseteq \mathbb {R} }](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%7B%5Cdisplaystyle%20%5B0%2C1%5D%5Csubseteq%20%5Cmathbb%20%7BR%7D%20%7D&fg=000000&font=TeX&svg=1) , which provides the probability measure on the set of all possible values of the random variable. Random variables are shown as Roman capital letters, often towards the end of the alphabet, such as

, which provides the probability measure on the set of all possible values of the random variable. Random variables are shown as Roman capital letters, often towards the end of the alphabet, such as  .

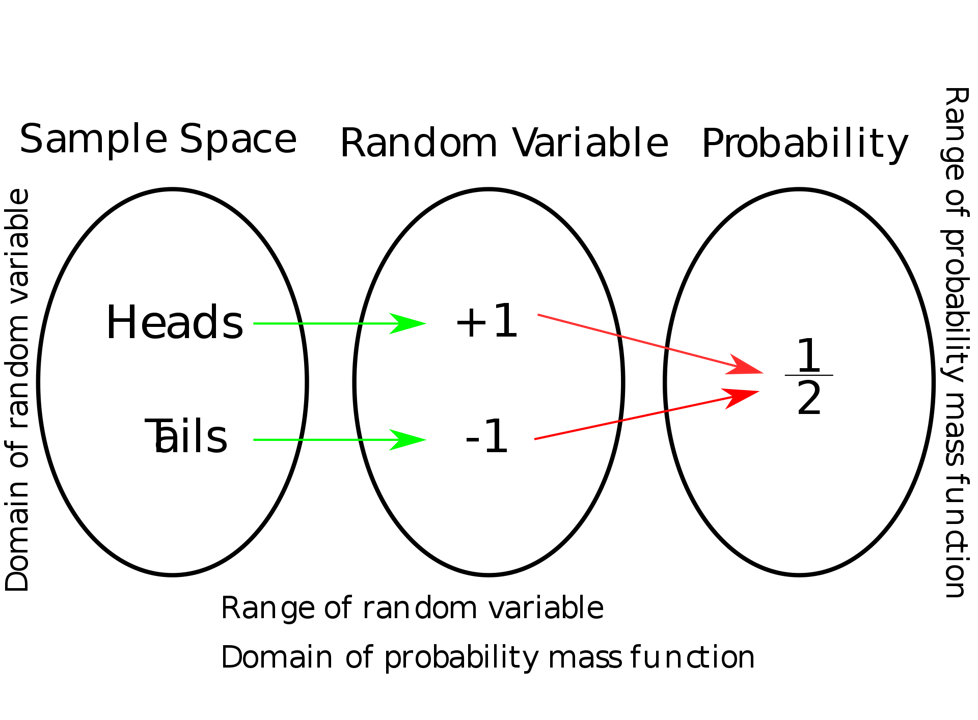

. to a measurable space of

to a measurable space of  , where 1 is correspondent to H and -1 is correspondent to T, utilizing a random variable of

, where 1 is correspondent to H and -1 is correspondent to T, utilizing a random variable of  =

=  = +1, written as

= +1, written as  .

.

for an event.

for an event. .

.![{\displaystyle F\colon \mathbb {R} \rightarrow [0,1]} {\displaystyle F\colon \mathbb {R} \rightarrow [0,1]}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%7B%5Cdisplaystyle%20F%5Ccolon%20%5Cmathbb%20%7BR%7D%20%5Crightarrow%20%5B0%2C1%5D%7D&fg=000000&font=TeX&svg=1) , where

, where  and

and  . Every function with these four properties is a CDF: for every such function, a random variable can be defined such that the function is the cumulative distribution function of that random variable.

. Every function with these four properties is a CDF: for every such function, a random variable can be defined such that the function is the cumulative distribution function of that random variable.![F(x)=P[X \leq x] F(x)=P[X \leq x]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=F%28x%29%3DP%5BX%20%5Cleq%20x%5D&fg=000000&font=TeX&svg=1)

,

, ,…, is a non-negative function f (x ), with f (

,…, is a non-negative function f (x ), with f ( ) giving the probability that X takes the value

) giving the probability that X takes the value

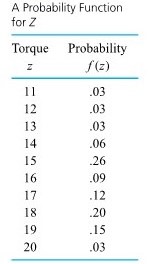

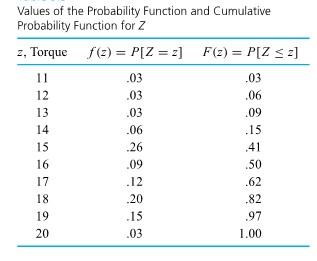

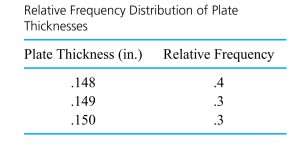

= the next measured torque for bolt 3 (recorded to the nearest integer), and we will treat Z as a discrete random variable. Now we want to give a plausible probility function for it. The relative frequencies for the bolt 3 torque measurements recorded introduce the relative frequency distribution:

= the next measured torque for bolt 3 (recorded to the nearest integer), and we will treat Z as a discrete random variable. Now we want to give a plausible probility function for it. The relative frequencies for the bolt 3 torque measurements recorded introduce the relative frequency distribution:

= the torque value selected.

= the torque value selected.

![F(16.3)=P[Z \leq 16.3]=P[Z \leq 16]=F(16)=.50 F(16.3)=P[Z \leq 16.3]=P[Z \leq 16]=F(16)=.50](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=F%2816.3%29%3DP%5BZ%20%5Cleq%2016.3%5D%3DP%5BZ%20%5Cleq%2016%5D%3DF%2816%29%3D.50&fg=000000&font=TeX&svg=1)

![F(32)=P[Z \leq 32]=1.00 F(32)=P[Z \leq 32]=1.00](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=F%2832%29%3DP%5BZ%20%5Cleq%2032%5D%3D1.00&fg=000000&font=TeX&svg=1)

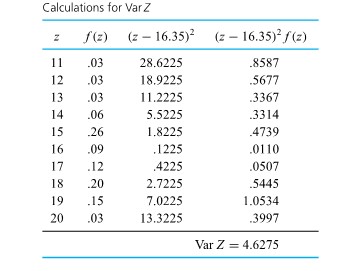

. Often the notation

. Often the notation  is used in place of Var X, and

is used in place of Var X, and  = 2.15 ft lb

= 2.15 ft lb

.

.

![X[latex] has the <strong>binomial (n, p) distribution</strong>.</div> <div> <div> <div class="textbox"> <strong>DEFINITION 3.2.5.1. Binomial Definition</strong> The binomial [latex](n, p) X[latex] has the <strong>binomial (n, p) distribution</strong>.</div> <div> <div> <div class="textbox"> <strong>DEFINITION 3.2.5.1. Binomial Definition</strong> The binomial [latex](n, p)](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=X%5Blatex%5D%20has%20the%20%3Cstrong%3Ebinomial%20%28n%2C%20p%29%20distribution%3C%2Fstrong%3E.%3C%2Fdiv%3E%20%20%3Cdiv%3E%20%20%3Cdiv%3E%20%20%3Cdiv%20class%3D%22textbox%22%3E%20%20%20%20%3Cstrong%3EDEFINITION%203.2.5.1.%20Binomial%20Definition%3C%2Fstrong%3E%20%20%20%20The%20binomial%20%5Blatex%5D%28n%2C%20p%29&fg=000000&font=TeX&svg=1) distribution is a discrete probability distribution with probability function

distribution is a discrete probability distribution with probability function

.

. for each trial producing a no go/failure outcome. And the

for each trial producing a no go/failure outcome. And the  term is a count of the number of patterns in which it would be possible to see

term is a count of the number of patterns in which it would be possible to see  nomial distribution derives from the fact that the values

nomial distribution derives from the fact that the values  are the terms in the expansion of

are the terms in the expansion of

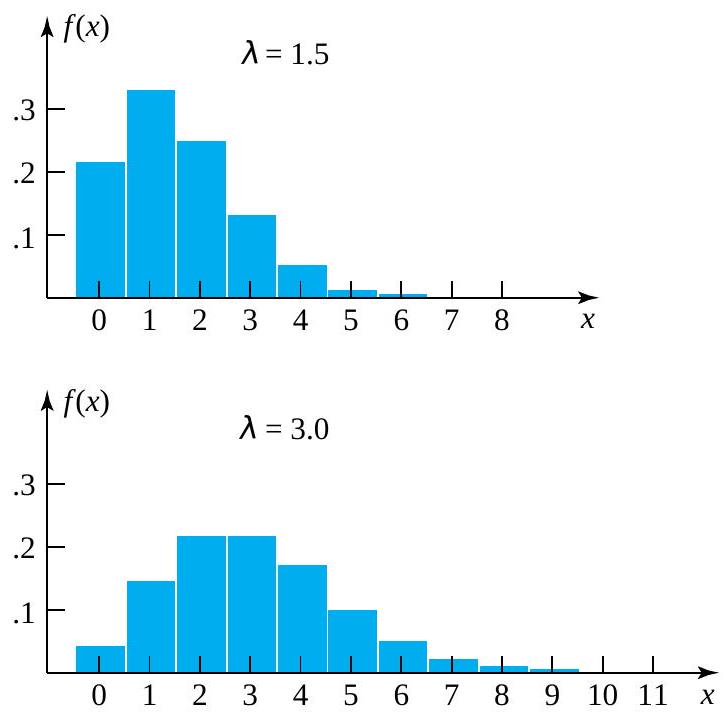

, the resulting histogram is right-skewed. For

, the resulting histogram is right-skewed. For  , the resulting histogram is left-skewed. The skewness increases as

, the resulting histogram is left-skewed. The skewness increases as

is indeed a sensible figure for the chance that a given shaft will be reworkable. Suppose further that

is indeed a sensible figure for the chance that a given shaft will be reworkable. Suppose further that

![\begin{aligned}P[\text { at least two reworkable shafts] } & =P[U \geq 2] \\& =f(2)+f(3)+\cdots+f(10) \\& =1-(f(0)+f(1)) \\& =1-\left(\frac{10 !}{0 ! 10 !}(.2)^{0}(.8)^{10}+\frac{10 !}{1 ! 9 !}(.2)^{1}(.8)^{9}\right) \\&=.62\end{aligned} \begin{aligned}P[\text { at least two reworkable shafts] } & =P[U \geq 2] \\& =f(2)+f(3)+\cdots+f(10) \\& =1-(f(0)+f(1)) \\& =1-\left(\frac{10 !}{0 ! 10 !}(.2)^{0}(.8)^{10}+\frac{10 !}{1 ! 9 !}(.2)^{1}(.8)^{9}\right) \\&=.62\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7DP%5B%5Ctext%20%7B%20at%20least%20two%20reworkable%20shafts%5D%20%7D%20%26%20%3DP%5BU%20%5Cgeq%202%5D%20%5C%5C%26%20%3Df%282%29%2Bf%283%29%2B%5Ccdots%2Bf%2810%29%20%5C%5C%26%20%3D1-%28f%280%29%2Bf%281%29%29%20%5C%5C%26%20%3D1-%5Cleft%28%5Cfrac%7B10%20%21%7D%7B0%20%21%2010%20%21%7D%28.2%29%5E%7B0%7D%28.8%29%5E%7B10%7D%2B%5Cfrac%7B10%20%21%7D%7B1%20%21%209%20%21%7D%28.2%29%5E%7B1%7D%28.8%29%5E%7B9%7D%5Cright%29%20%5C%5C%26%3D.62%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

's have to sum up to 1 , is a common and useful one.)

's have to sum up to 1 , is a common and useful one.) , and the . 62 figure largely irrelevant. (The independence-of-trials assumption would be inappropriate in this situation.)

, and the . 62 figure largely irrelevant. (The independence-of-trials assumption would be inappropriate in this situation.)

.

. from it.

from it.

is obtained as follows. Possible values for

is obtained as follows. Possible values for ![\begin{aligned}f(0)= & P[V=0] \\= & P[\text { first pellet selected is nonconforming and } \\& \text { subsequently the second pellet is also nonconforming }] \\f(2)= & P[V=2] \\= & P[\text { first pellet selected is conforming and } \\& \text { subsequently the second pellet selected is conforming }] \\f(1)= & 1-(f(0)+f(2))\end{aligned} \begin{aligned}f(0)= & P[V=0] \\= & P[\text { first pellet selected is nonconforming and } \\& \text { subsequently the second pellet is also nonconforming }] \\f(2)= & P[V=2] \\= & P[\text { first pellet selected is conforming and } \\& \text { subsequently the second pellet selected is conforming }] \\f(1)= & 1-(f(0)+f(2))\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7Df%280%29%3D%20%26%20P%5BV%3D0%5D%20%5C%5C%3D%20%26%20P%5B%5Ctext%20%7B%20first%20pellet%20selected%20is%20nonconforming%20and%20%7D%20%5C%5C%26%20%5Ctext%20%7B%20subsequently%20the%20second%20pellet%20is%20also%20nonconforming%20%7D%5D%20%5C%5Cf%282%29%3D%20%26%20P%5BV%3D2%5D%20%5C%5C%3D%20%26%20P%5B%5Ctext%20%7B%20first%20pellet%20selected%20is%20conforming%20and%20%7D%20%5C%5C%26%20%5Ctext%20%7B%20subsequently%20the%20second%20pellet%20selected%20is%20conforming%20%7D%5D%20%5C%5Cf%281%29%3D%20%26%201-%28f%280%29%2Bf%282%29%29%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

is

is

to

to  . Nevertheless, for most practical purposes,

. Nevertheless, for most practical purposes,  . To see this, note that

. To see this, note that

is not too extreme, and a binomial distribution is a decent description of a variable arising from simple random sampling.

is not too extreme, and a binomial distribution is a decent description of a variable arising from simple random sampling.

distribution

distribution

.

. . One is then led to the binomial

. One is then led to the binomial  ) distribution. In fact, for large

) distribution. In fact, for large  probability function approximates the one specified in equation (5.10). So one might think of the Poisson distribution for counts as arising through a mechanism that would present many tiny similar opportunities for independent occurrence or non-occurrence throughout an interval of time or space.

probability function approximates the one specified in equation (5.10). So one might think of the Poisson distribution for counts as arising through a mechanism that would present many tiny similar opportunities for independent occurrence or non-occurrence throughout an interval of time or space.

, whose probability histograms peak near their respective

, whose probability histograms peak near their respective

-Particles

-Particles .

.

[at least 4 particles are recorded]

[at least 4 particles are recorded]![=P[S \geq 4] =P[S \geq 4]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%3DP%5BS%20%5Cgeq%204%5D&fg=000000&font=TeX&svg=1)

, the reasonable choice of

, the reasonable choice of

![\begin{aligned}P[10 \leq M \leq 15]= & f(10)+f(11)+f(12)+f(13)+f(14)+f(15) \\= & \frac{e^{-12.5}(12.5)^{10}}{10 !}+\frac{e^{-12.5}(12.5)^{11}}{11 !}+\frac{e^{-12.5}(12.5)^{12}}{12 !} \\& +\frac{e^{-12.5}(12.5)^{13}}{13 !}+\frac{e^{-12.5}(12.5)^{14}}{14 !}+\frac{e^{-12.5}(12.5)^{15}}{15 !} \\= & .60\end{aligned} \begin{aligned}P[10 \leq M \leq 15]= & f(10)+f(11)+f(12)+f(13)+f(14)+f(15) \\= & \frac{e^{-12.5}(12.5)^{10}}{10 !}+\frac{e^{-12.5}(12.5)^{11}}{11 !}+\frac{e^{-12.5}(12.5)^{12}}{12 !} \\& +\frac{e^{-12.5}(12.5)^{13}}{13 !}+\frac{e^{-12.5}(12.5)^{14}}{14 !}+\frac{e^{-12.5}(12.5)^{15}}{15 !} \\= & .60\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7DP%5B10%20%5Cleq%20M%20%5Cleq%2015%5D%3D%20%26%20f%2810%29%2Bf%2811%29%2Bf%2812%29%2Bf%2813%29%2Bf%2814%29%2Bf%2815%29%20%5C%5C%3D%20%26%20%5Cfrac%7Be%5E%7B-12.5%7D%2812.5%29%5E%7B10%7D%7D%7B10%20%21%7D%2B%5Cfrac%7Be%5E%7B-12.5%7D%2812.5%29%5E%7B11%7D%7D%7B11%20%21%7D%2B%5Cfrac%7Be%5E%7B-12.5%7D%2812.5%29%5E%7B12%7D%7D%7B12%20%21%7D%20%5C%5C%26%20%2B%5Cfrac%7Be%5E%7B-12.5%7D%2812.5%29%5E%7B13%7D%7D%7B13%20%21%7D%2B%5Cfrac%7Be%5E%7B-12.5%7D%2812.5%29%5E%7B14%7D%7D%7B14%20%21%7D%2B%5Cfrac%7Be%5E%7B-12.5%7D%2812.5%29%5E%7B15%7D%7D%7B15%20%21%7D%20%5C%5C%3D%20%26%20.60%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

= 1

= 1

to represent the curve.

to represent the curve.  f (x ) dx values as dx gets small. (In mechanics,

f (x ) dx values as dx gets small. (In mechanics,  X

X f(t) dt

f(t) dt F(x) = f(x)

F(x) = f(x)

and

and  . P(c<x<d) is the area under the curve, above the x-axis, to the right of

. P(c<x<d) is the area under the curve, above the x-axis, to the right of  . The probability that

. The probability that  and

and  ). Since the probability is equal to the area, the probability is also zero.

). Since the probability is equal to the area, the probability is also zero. because probability is equal to area.

because probability is equal to area. .

.

is used in place of Var X ,and σ is used in place of

is used in place of Var X ,and σ is used in place of

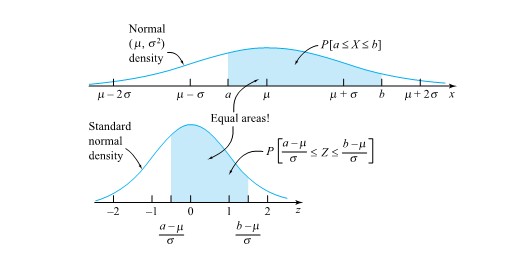

(remember that the standard deviation =

(remember that the standard deviation =  = σ). Figure 4.1.3.1 shows the notation for the standard normal distribution, and that the distribution shape depends on these parameters. Since the area under the curve must equal one, a change in the standard deviation, σ, causes a change in the shape of the curve; the curve becomes fatter or skinnier depending on σ. A change in μ causes the graph to shift to the left or right. This means there are an infinite number of normal probability distributions.

= σ). Figure 4.1.3.1 shows the notation for the standard normal distribution, and that the distribution shape depends on these parameters. Since the area under the curve must equal one, a change in the standard deviation, σ, causes a change in the shape of the curve; the curve becomes fatter or skinnier depending on σ. A change in μ causes the graph to shift to the left or right. This means there are an infinite number of normal probability distributions.

![P[a \leq X \leq b]=\int_a^b \frac{1}{\sqrt{2 \pi \sigma^2}} e^{-(x-\mu)^2 / 2 \sigma^2} d x=\int_{(a-\mu) / \sigma}^{(b-\mu) / \sigma} \frac{1}{\sqrt{2 \pi}} e^{-z^2 / 2} d z P[a \leq X \leq b]=\int_a^b \frac{1}{\sqrt{2 \pi \sigma^2}} e^{-(x-\mu)^2 / 2 \sigma^2} d x=\int_{(a-\mu) / \sigma}^{(b-\mu) / \sigma} \frac{1}{\sqrt{2 \pi}} e^{-z^2 / 2} d z](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5Ba%20%5Cleq%20X%20%5Cleq%20b%5D%3D%5Cint_a%5Eb%20%5Cfrac%7B1%7D%7B%5Csqrt%7B2%20%5Cpi%20%5Csigma%5E2%7D%7D%20e%5E%7B-%28x-%5Cmu%29%5E2%20%2F%202%20%5Csigma%5E2%7D%20d%20x%3D%5Cint_%7B%28a-%5Cmu%29%20%2F%20%5Csigma%7D%5E%7B%28b-%5Cmu%29%20%2F%20%5Csigma%7D%20%5Cfrac%7B1%7D%7B%5Csqrt%7B2%20%5Cpi%7D%7D%20e%5E%7B-z%5E2%20%2F%202%7D%20d%20z&fg=000000&font=TeX&svg=1)

and a value x associated with X , one converts to units of standard deviations above the mean via:

and a value x associated with X , one converts to units of standard deviations above the mean via:

is used to stand for the standard normal cumulative probability function, instead of the more generic F.

is used to stand for the standard normal cumulative probability function, instead of the more generic F. , the standard normal quantile function,

, the standard normal quantile function,

is not just a standard normal phenomenon but is true in general

is not just a standard normal phenomenon but is true in general

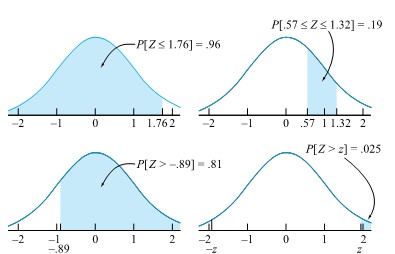

= .025 in the right tail of the standard normal

= .025 in the right tail of the standard normal = .975. Locating .975 in the table body, one sees that z = 1.96.

= .975. Locating .975 in the table body, one sees that z = 1.96.

= 134.0 and w

= 134.0 and w = 136.0 are converted to z-values (or units of standard deviations above the mean) as

= 136.0 are converted to z-values (or units of standard deviations above the mean) as

, giving the probability that (simultaneously)

, giving the probability that (simultaneously)  . That is,

. That is,![f(x, y)=P[X=x \text { and } Y=y] f(x, y)=P[X=x \text { and } Y=y]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=f%28x%2C%20y%29%3DP%5BX%3Dx%20%5Ctext%20%7B%20and%20%7D%20Y%3Dy%5D&fg=000000&font=TeX&svg=1)

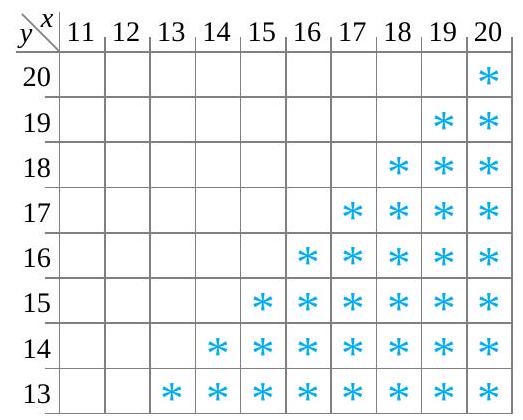

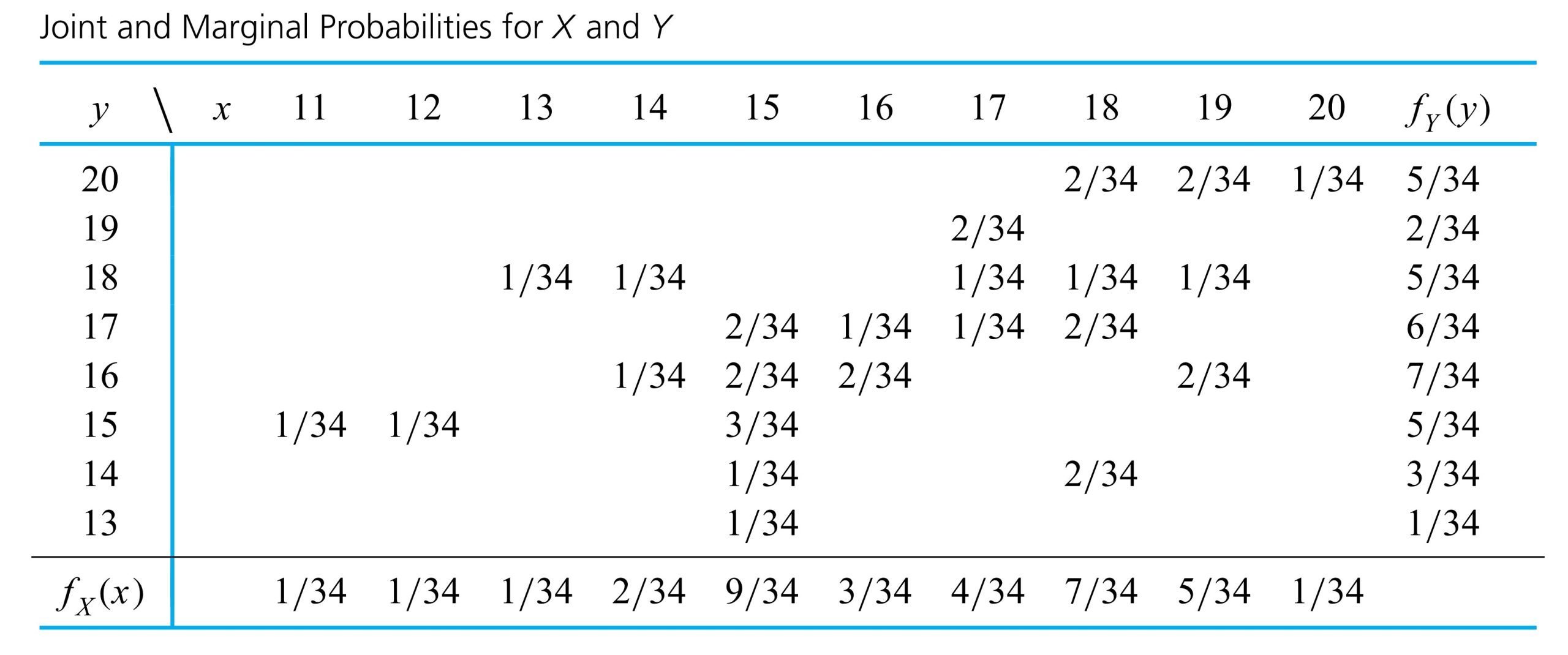

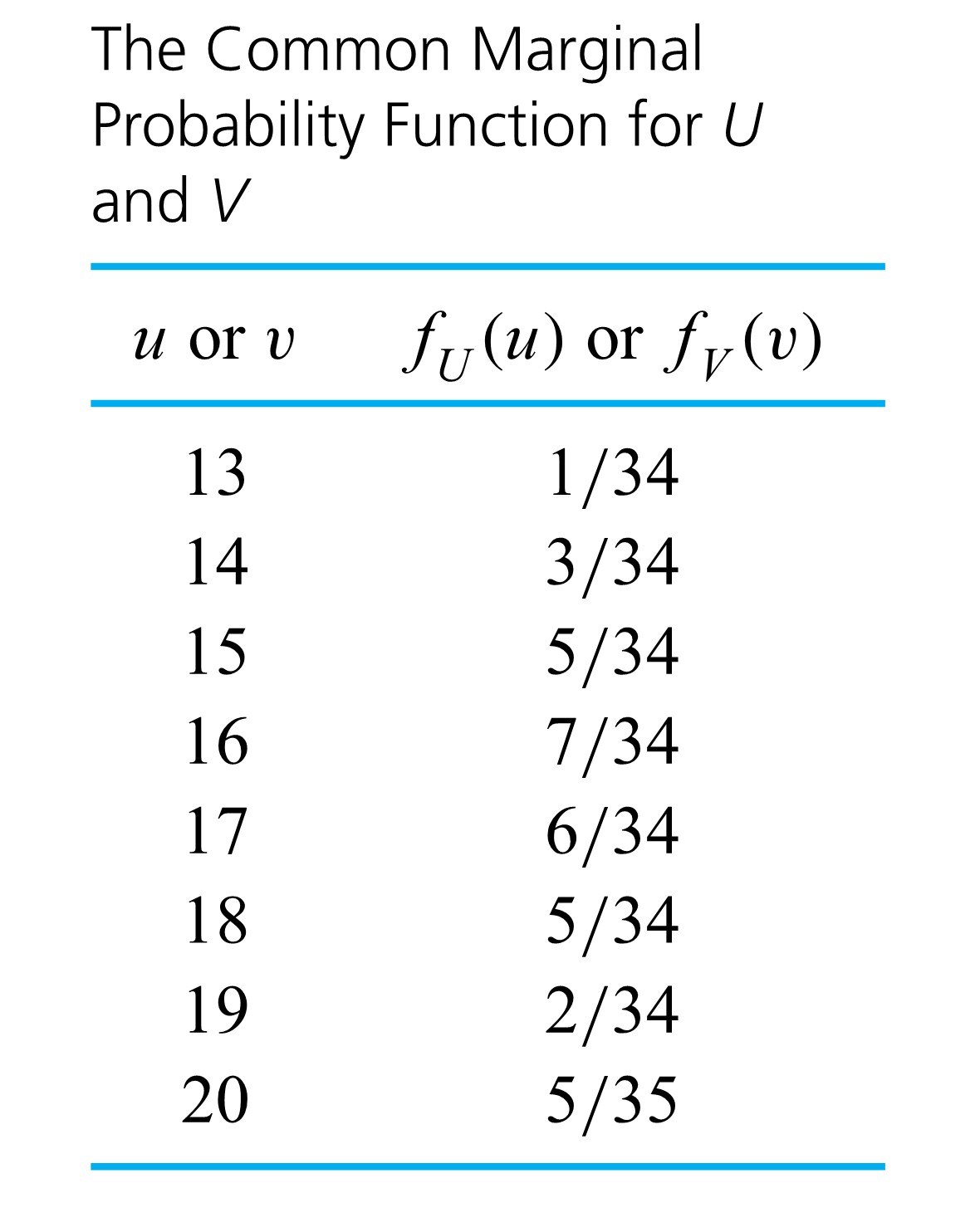

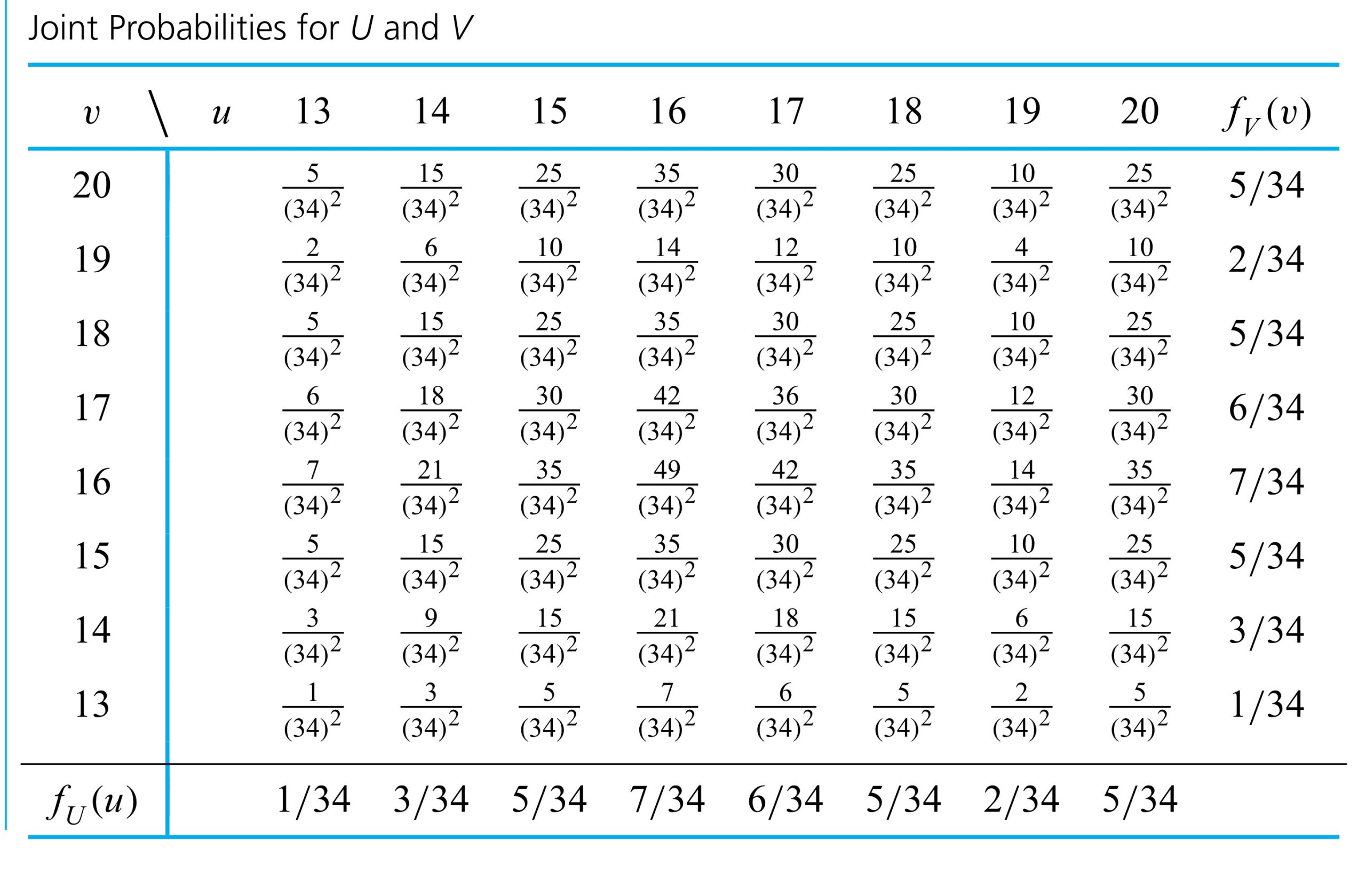

the next torque recorded for bolt 3

the next torque recorded for bolt 3 the next torque recorded for bolt 4

the next torque recorded for bolt 4 and

and ![Y=18] Y=18]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=Y%3D18%5D&fg=000000&font=TeX&svg=1) might be

might be  , the relative frequency of this pair in the data set. Similarly, the assignments

, the relative frequency of this pair in the data set. Similarly, the assignments![\begin{aligned}& P[X=18 \text { and } Y=17]=\frac{2}{34} \\& P[X=14 \text { and } Y=9]=0\end{aligned} \begin{aligned}& P[X=18 \text { and } Y=17]=\frac{2}{34} \\& P[X=14 \text { and } Y=9]=0\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7D%26%20P%5BX%3D18%20%5Ctext%20%7B%20and%20%7D%20Y%3D17%5D%3D%5Cfrac%7B2%7D%7B34%7D%20%5C%5C%26%20P%5BX%3D14%20%5Ctext%20%7B%20and%20%7D%20Y%3D9%5D%3D0%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

![[0,1] [0,1]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5B0%2C1%5D&fg=000000&font=TeX&svg=1) and that they total to 1 . By summing up just some of the

and that they total to 1 . By summing up just some of the ![\begin{aligned}& P[X\geq Y], \\& P[|X-Y|\leq 1], \\& \text { and } P[X=17]\end{aligned} \begin{aligned}& P[X\geq Y], \\& P[|X-Y|\leq 1], \\& \text { and } P[X=17]\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7D%26%20P%5BX%5Cgeq%20Y%5D%2C%20%5C%5C%26%20P%5B%7CX-Y%7C%5Cleq%201%5D%2C%20%5C%5C%26%20%5Ctext%20%7B%20and%20%7D%20P%5BX%3D17%5D%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

![P[X \geq Y] P[X \geq Y]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5BX%20%5Cgeq%20Y%5D&fg=000000&font=TeX&svg=1) , the probability that the measured bolt 3 torque is at least as big as the measured bolt 4 torque. Figure 4.2.1.1 indicates with asterisks which possible combinations of

, the probability that the measured bolt 3 torque is at least as big as the measured bolt 4 torque. Figure 4.2.1.1 indicates with asterisks which possible combinations of ![\begin{aligned}P[X \geq Y]= & f(15,13)+f(15,14)+f(15,15)+f(16,16) \\& +f(17,17)+f(18,14)+f(18,17)+f(18,18) \\& +f(19,16)+f(19,18)+f(20,20) \\= & \frac{1}{34}+\frac{1}{34}+\frac{3}{34}+\frac{2}{34}+\cdots+\frac{1}{34}=\frac{17}{34}\end{aligned} \begin{aligned}P[X \geq Y]= & f(15,13)+f(15,14)+f(15,15)+f(16,16) \\& +f(17,17)+f(18,14)+f(18,17)+f(18,18) \\& +f(19,16)+f(19,18)+f(20,20) \\= & \frac{1}{34}+\frac{1}{34}+\frac{3}{34}+\frac{2}{34}+\cdots+\frac{1}{34}=\frac{17}{34}\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7DP%5BX%20%5Cgeq%20Y%5D%3D%20%26%20f%2815%2C13%29%2Bf%2815%2C14%29%2Bf%2815%2C15%29%2Bf%2816%2C16%29%20%5C%5C%26%20%2Bf%2817%2C17%29%2Bf%2818%2C14%29%2Bf%2818%2C17%29%2Bf%2818%2C18%29%20%5C%5C%26%20%2Bf%2819%2C16%29%2Bf%2819%2C18%29%2Bf%2820%2C20%29%20%5C%5C%3D%20%26%20%5Cfrac%7B1%7D%7B34%7D%2B%5Cfrac%7B1%7D%7B34%7D%2B%5Cfrac%7B3%7D%7B34%7D%2B%5Cfrac%7B2%7D%7B34%7D%2B%5Ccdots%2B%5Cfrac%7B1%7D%7B34%7D%3D%5Cfrac%7B17%7D%7B34%7D%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

![P[|X-Y| \leq 1] P[|X-Y| \leq 1]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5B%7CX-Y%7C%20%5Cleq%201%5D&fg=000000&font=TeX&svg=1) -the probability that the bolt 3 and 4 torques are within

-the probability that the bolt 3 and 4 torques are within  of each other. Figure 4.2.1.2 shows combinations of

of each other. Figure 4.2.1.2 shows combinations of ![\begin{aligned}P[|X-Y| \leq 1]= & f(15,14)+f(15,15)+f(15,16)+f(16,16) \\& +f(16,17)+f(17,17)+f(17,18)+f(18,17) \\& +f(18,18)+f(19,18)+f(19,20)+f(20,20)=\frac{18}{34}\end{aligned} \begin{aligned}P[|X-Y| \leq 1]= & f(15,14)+f(15,15)+f(15,16)+f(16,16) \\& +f(16,17)+f(17,17)+f(17,18)+f(18,17) \\& +f(18,18)+f(19,18)+f(19,20)+f(20,20)=\frac{18}{34}\end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7DP%5B%7CX-Y%7C%20%5Cleq%201%5D%3D%20%26%20f%2815%2C14%29%2Bf%2815%2C15%29%2Bf%2815%2C16%29%2Bf%2816%2C16%29%20%5C%5C%26%20%2Bf%2816%2C17%29%2Bf%2817%2C17%29%2Bf%2817%2C18%29%2Bf%2818%2C17%29%20%5C%5C%26%20%2Bf%2818%2C18%29%2Bf%2819%2C18%29%2Bf%2819%2C20%29%2Bf%2820%2C20%29%3D%5Cfrac%7B18%7D%7B34%7D%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

![P[X=17] P[X=17]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5BX%3D17%5D&fg=000000&font=TeX&svg=1) , the probability that the measured bolt 3 torque is

, the probability that the measured bolt 3 torque is  , is obtained by adding down the

, is obtained by adding down the  column in Table 4.2.1.1. That is,

column in Table 4.2.1.1. That is,![\begin{aligned} P[X=17] & =f(17,17)+f(17,18)+f(17,19) \\ & =\frac{1}{34}+\frac{1}{34}+\frac{2}{34} \\ & =\frac{4}{34} \end{aligned} \begin{aligned} P[X=17] & =f(17,17)+f(17,18)+f(17,19) \\ & =\frac{1}{34}+\frac{1}{34}+\frac{2}{34} \\ & =\frac{4}{34} \end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7D%20P%5BX%3D17%5D%20%26%20%3Df%2817%2C17%29%2Bf%2817%2C18%29%2Bf%2817%2C19%29%20%5C%5C%20%26%20%3D%5Cfrac%7B1%7D%7B34%7D%2B%5Cfrac%7B1%7D%7B34%7D%2B%5Cfrac%7B2%7D%7B34%7D%20%5C%5C%20%26%20%3D%5Cfrac%7B4%7D%7B34%7D%20%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

. And one can add across rows in the same table to get values for the probability function of

. And one can add across rows in the same table to get values for the probability function of  . One can then write these sums in the margins of the two-way table. So it should not be surprising that probability distributions for individual random variables obtained from their joint distribution are called marginal distributions. A formal statement of this terminology in the case of two discrete variables is next.

. One can then write these sums in the margins of the two-way table. So it should not be surprising that probability distributions for individual random variables obtained from their joint distribution are called marginal distributions. A formal statement of this terminology in the case of two discrete variables is next.

and

and  are known, is there then exactly one choice for

are known, is there then exactly one choice for

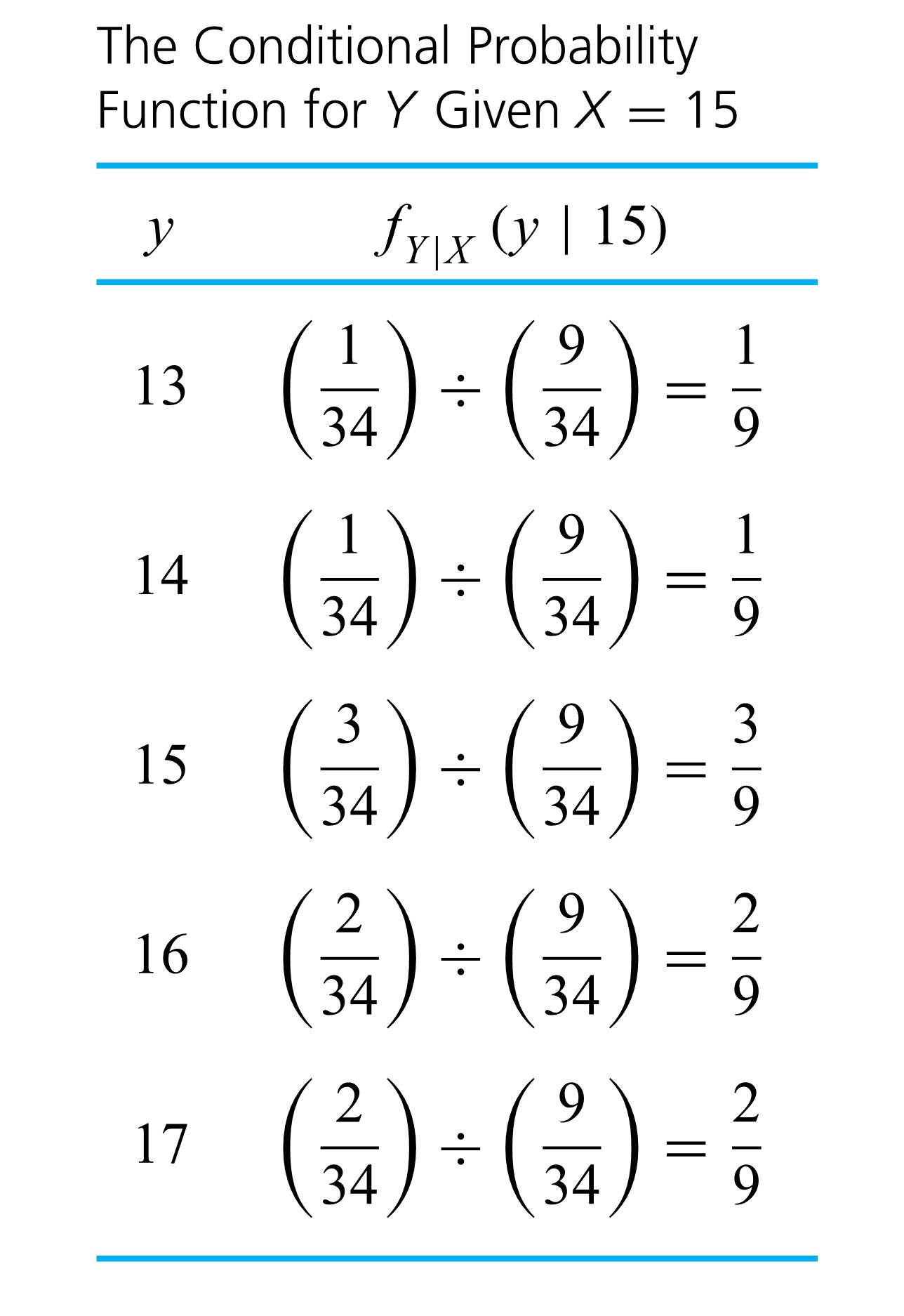

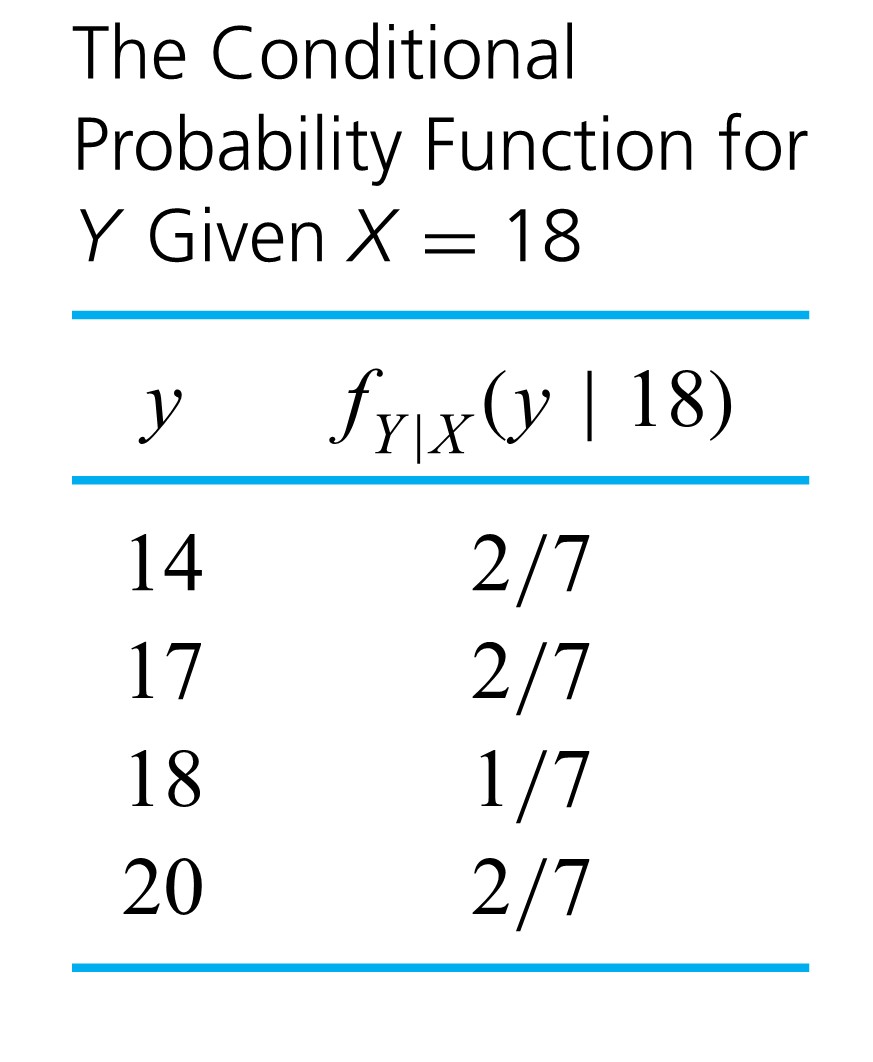

torque situation, a technician who has just loosened bolt 3 and measured the torque as

torque situation, a technician who has just loosened bolt 3 and measured the torque as  ought to have expectations for bolt 4 torque

ought to have expectations for bolt 4 torque  somewhat different from those described by the marginal distribution in Table 4.2.1.3. After all, returning to the data in that led to Table 4.2.1.1, the relative frequency distribution of bolt 4 torques for those components with bolt 3 torque of

somewhat different from those described by the marginal distribution in Table 4.2.1.3. After all, returning to the data in that led to Table 4.2.1.1, the relative frequency distribution of bolt 4 torques for those components with bolt 3 torque of  ought to make a probability distribution for

ought to make a probability distribution for

is the function of

is the function of

given

given  is the function of

is the function of

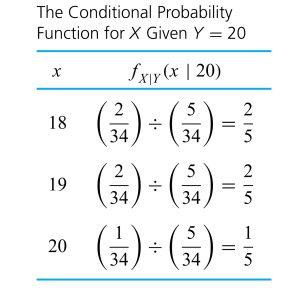

), so that they are renormalized to total to 1 . Similarly, equation (4.2.2.3) says that looking only at the column specified by

), so that they are renormalized to total to 1 . Similarly, equation (4.2.2.3) says that looking only at the column specified by  , the appropriate conditional distribution for

, the appropriate conditional distribution for

. So dividing values in the

. So dividing values in the

specified by

specified by

, shown in Table 4.2.2.3 . Tables 4.2.2.2 and 4.2.4.3 confirm that the conditional distributions of

, shown in Table 4.2.2.3 . Tables 4.2.2.2 and 4.2.4.3 confirm that the conditional distributions of

. In this situation, equation (4.2.2.2) gives

. In this situation, equation (4.2.2.2) gives

row of Table 4.2.1..2 divided by the marginal

row of Table 4.2.1..2 divided by the marginal  is given in Table 4.2.2.4.

is given in Table 4.2.2.4.

provides some information about

provides some information about

and

and

, one clearly wants

, one clearly wants![f(13,13)=P[U=13 \text { and } V=13]=0 f(13,13)=P[U=13 \text { and } V=13]=0](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=f%2813%2C13%29%3DP%5BU%3D13%20%5Ctext%20%7B%20and%20%7D%20V%3D13%5D%3D0&fg=000000&font=TeX&svg=1)

slips labeled with torques with relative frequencies as in Table 4.2.2.6. Then even if sampling is done without replacement, the probabilities developed earlier for

slips labeled with torques with relative frequencies as in Table 4.2.2.6. Then even if sampling is done without replacement, the probabilities developed earlier for

is much larger than the sample size

is much larger than the sample size  all have the same marginal distribution and are independent, they are termed iid or independent and identically distributed.

all have the same marginal distribution and are independent, they are termed iid or independent and identically distributed. , the object is to predict the behavior of the random variable

, the object is to predict the behavior of the random variable

are

are  are

are  constants, then the random variable

constants, then the random variable  has mean

has mean

and the other

and the other  ‘s equal to plus and minus 1 ‘s.

‘s equal to plus and minus 1 ‘s. , and

, and

and [/latex]\operatorname{Var} U[/latex], there is no need to go through the intermediate step of deriving the distribution of

and [/latex]\operatorname{Var} U[/latex], there is no need to go through the intermediate step of deriving the distribution of  . That is, in cases where random variables

. That is, in cases where random variables

and

and

![\begin{aligned}\operatorname{Var} \bar{X} & =\left(\frac{1}{n}\right)^{2} \operatorname{Var} X_{1}+\left(\frac{1}{n}\right)^{2} \operatorname{Var} X_{2}+\cdots+\left(\frac{1}{n}\right)^{2} \operatorname{Var} X_{n} \\& =n\left(\frac{1}{n}\right)^{2} \sigma^{2}=\frac{\sigma^{2}}{n}\end{aligned}</div> </div></blockquote> <div>.</div> <div>Since [latex]\sigma^{2} / n \begin{aligned}\operatorname{Var} \bar{X} & =\left(\frac{1}{n}\right)^{2} \operatorname{Var} X_{1}+\left(\frac{1}{n}\right)^{2} \operatorname{Var} X_{2}+\cdots+\left(\frac{1}{n}\right)^{2} \operatorname{Var} X_{n} \\& =n\left(\frac{1}{n}\right)^{2} \sigma^{2}=\frac{\sigma^{2}}{n}\end{aligned}</div> </div></blockquote> <div>.</div> <div>Since [latex]\sigma^{2} / n](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7D%5Coperatorname%7BVar%7D%20%5Cbar%7BX%7D%20%26%20%3D%5Cleft%28%5Cfrac%7B1%7D%7Bn%7D%5Cright%29%5E%7B2%7D%20%5Coperatorname%7BVar%7D%20X_%7B1%7D%2B%5Cleft%28%5Cfrac%7B1%7D%7Bn%7D%5Cright%29%5E%7B2%7D%20%5Coperatorname%7BVar%7D%20X_%7B2%7D%2B%5Ccdots%2B%5Cleft%28%5Cfrac%7B1%7D%7Bn%7D%5Cright%29%5E%7B2%7D%20%5Coperatorname%7BVar%7D%20X_%7Bn%7D%20%5C%5C%26%20%3Dn%5Cleft%28%5Cfrac%7B1%7D%7Bn%7D%5Cright%29%5E%7B2%7D%20%5Csigma%5E%7B2%7D%3D%5Cfrac%7B%5Csigma%5E%7B2%7D%7D%7Bn%7D%5Cend%7Baligned%7D%3C%2Fdiv%3E%20%20%3C%2Fdiv%3E%3C%2Fblockquote%3E%20%20%3Cdiv%3E.%3C%2Fdiv%3E%20%20%3Cdiv%3ESince%20%5Blatex%5D%5Csigma%5E%7B2%7D%20%2F%20n&fg=000000&font=TeX&svg=1) is decreasing in

is decreasing in  having a probability distribution centered at the population mean

having a probability distribution centered at the population mean ![\bar{X}/[latex] under random sampling with replacement, are also approximate descriptions of the behavior of [latex]\bar{X} \bar{X}/[latex] under random sampling with replacement, are also approximate descriptions of the behavior of [latex]\bar{X}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbar%7BX%7D%2F%5Blatex%5D%20under%20random%20sampling%20with%20replacement%2C%20are%20also%20approximate%20descriptions%20of%20the%20behavior%20of%20%5Blatex%5D%5Cbar%7BX%7D&fg=000000&font=TeX&svg=1) under simple random sampling in enumerative contexts. (Recall the discussion about the approximate independence of observations resulting from simple random sampling of large populations.)

under simple random sampling in enumerative contexts. (Recall the discussion about the approximate independence of observations resulting from simple random sampling of large populations.) .)

.) the last digit of the serial number observed next Monday at 9 A.M.

the last digit of the serial number observed next Monday at 9 A.M. the last digit of the serial number observed the following Monday at 9 A.M.

the last digit of the serial number observed the following Monday at 9 A.M. is that they are independent, each with the marginal probability function

is that they are independent, each with the marginal probability function

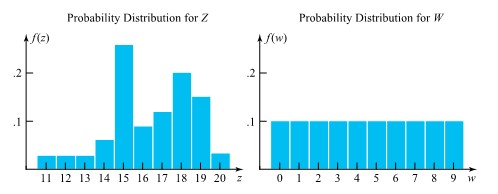

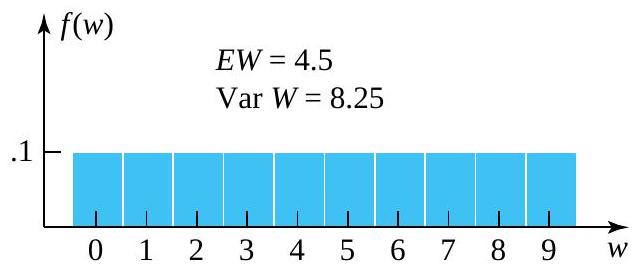

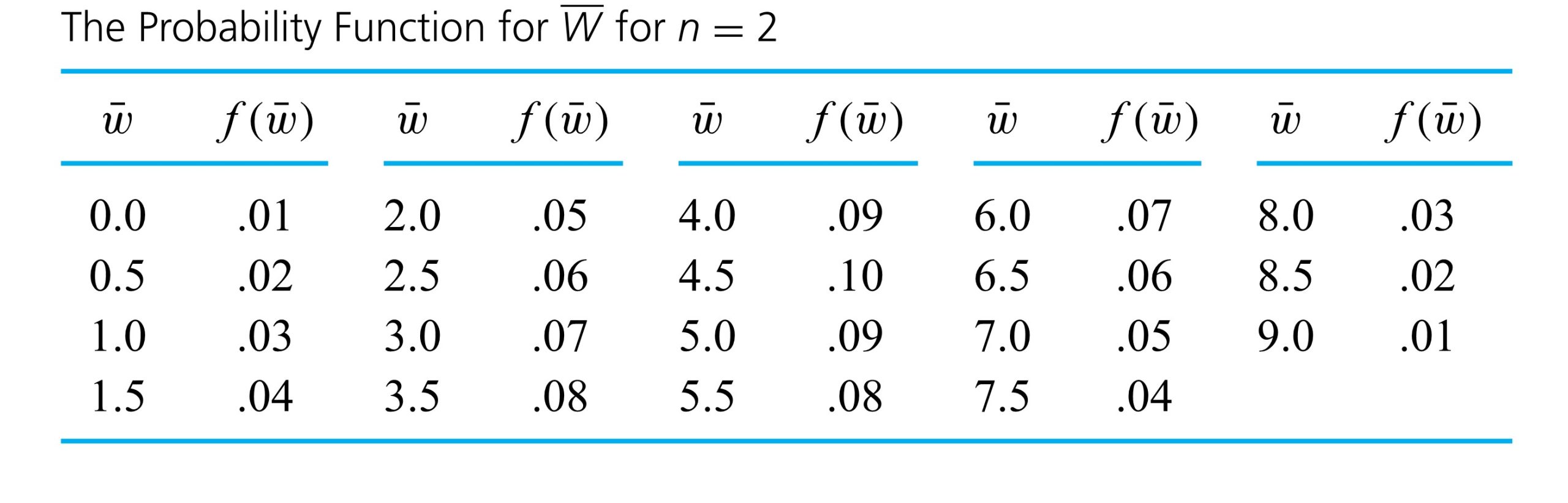

has the probability function given in Table 4.2.2.1 and pictured in Figure 4.2.2.2

has the probability function given in Table 4.2.2.1 and pictured in Figure 4.2.2.2

and the small sample size of

and the small sample size of  looks far more bell-shaped than the underlying distribution. It is clear why this is so. As you move away from the mean or central value of

looks far more bell-shaped than the underlying distribution. It is clear why this is so. As you move away from the mean or central value of  and

and  that can produce a given value of

that can produce a given value of  . For example, to observe

. For example, to observe  , you must have

, you must have  and

and  -that is, you must observe not one but two extreme values. On the other hand, there are ten different combinations of

-that is, you must observe not one but two extreme values. On the other hand, there are ten different combinations of  .

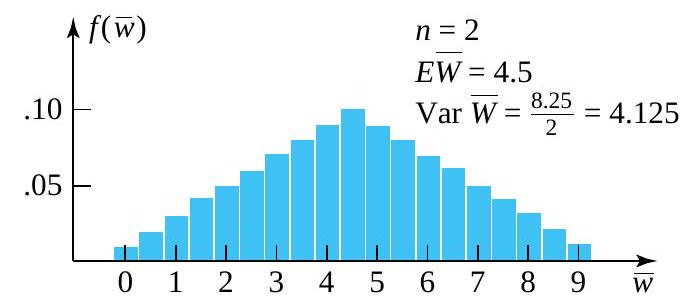

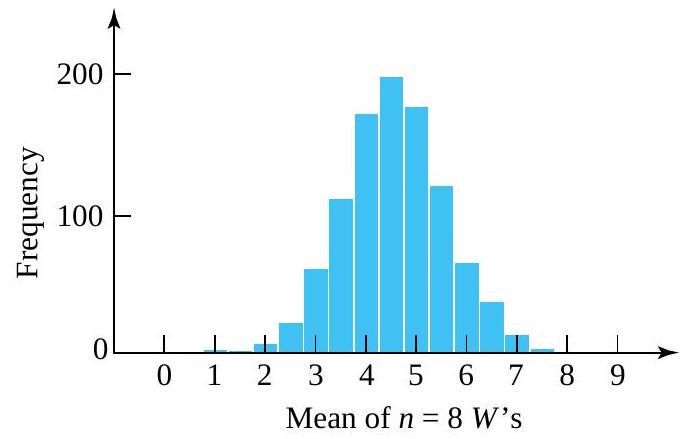

. (with marginal distribution were simulated and each set averaged to produce 1,000 simulated values of

(with marginal distribution were simulated and each set averaged to produce 1,000 simulated values of  . Figure 4.2.2.3 is a histogram of these 1,000 values. Notice the bell-shaped character of the plot. (The simulated mean of

. Figure 4.2.2.3 is a histogram of these 1,000 values. Notice the bell-shaped character of the plot. (The simulated mean of  , while the variance of

, while the variance of  , in close agreement with formulas.)

, in close agreement with formulas.)

or so is adequate to make

or so is adequate to make  excess service times, to produce

excess service times, to produce the sample mean time (over a

the sample mean time (over a  threshold) required to complete the next 100 stamp sales

threshold) required to complete the next 100 stamp sales![P[\bar{S}>17] P[\bar{S}>17]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5B%5Cbar%7BS%7D%3E17%5D&fg=000000&font=TeX&svg=1) .

. distribution is plausible for the individual excess service times,

distribution is plausible for the individual excess service times,

, via formulas. Further, in view of the fact that

, via formulas. Further, in view of the fact that

-values before consulting the standard normal table. In this case, the mean and standard deviation to be used are (respectively)

-values before consulting the standard normal table. In this case, the mean and standard deviation to be used are (respectively)  and

and  . That is, a

. That is, a

![P[\bar{S}>17] \approx P[Z>.30]=1-\Phi(.30)=.38 P[\bar{S}>17] \approx P[Z>.30]=1-\Phi(.30)=.38](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5B%5Cbar%7BS%7D%3E17%5D%20%5Capprox%20P%5BZ%3E.30%5D%3D1-%5CPhi%28.30%29%3D.38&fg=000000&font=TeX&svg=1)

.3 g

.3 g

< z

< z

![P\left[\bar{x}-1.645 \frac{s}{\sqrt{n}}<\mu<\bar{x}+1.645 \frac{s}{\sqrt{n}}\right] \approx .90 P\left[\bar{x}-1.645 \frac{s}{\sqrt{n}}<\mu<\bar{x}+1.645 \frac{s}{\sqrt{n}}\right] \approx .90](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5Cleft%5B%5Cbar%7Bx%7D-1.645%20%5Cfrac%7Bs%7D%7B%5Csqrt%7Bn%7D%7D%3C%5Cmu%3C%5Cbar%7Bx%7D%2B1.645%20%5Cfrac%7Bs%7D%7B%5Csqrt%7Bn%7D%7D%5Cright%5D%20%5Capprox%20.90&fg=000000&font=TeX&svg=1)

. Setting

. Setting

.

.

.It is of the same form as the corresponding null hypothesis, except that the equality sign

.It is of the same form as the corresponding null hypothesis, except that the equality sign

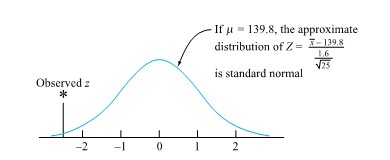

itself. Using form (5.1.2.4), the reference distribution will always be the same—namely, standard normal.

itself. Using form (5.1.2.4), the reference distribution will always be the same—namely, standard normal. 139.8.

139.8.

![\begin{aligned} & P[\text { a standard normal variable } \leq-2.5] \\ & \quad+P[\text { a standard normal variable } \geq 2.5] \\ & \quad=P[\mid \text { a standard normal variable } \mid \geq 2.5] \\ & \quad=.01 \end{aligned} \begin{aligned} & P[\text { a standard normal variable } \leq-2.5] \\ & \quad+P[\text { a standard normal variable } \geq 2.5] \\ & \quad=P[\mid \text { a standard normal variable } \mid \geq 2.5] \\ & \quad=.01 \end{aligned}](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=%5Cbegin%7Baligned%7D%20%26%20P%5B%5Ctext%20%7B%20a%20standard%20normal%20variable%20%7D%20%5Cleq-2.5%5D%20%5C%5C%20%26%20%5Cquad%2BP%5B%5Ctext%20%7B%20a%20standard%20normal%20variable%20%7D%20%5Cgeq%202.5%5D%20%5C%5C%20%26%20%5Cquad%3DP%5B%5Cmid%20%5Ctext%20%7B%20a%20standard%20normal%20variable%20%7D%20%5Cmid%20%5Cgeq%202.5%5D%20%5C%5C%20%26%20%5Cquad%3D.01%20%5Cend%7Baligned%7D&fg=000000&font=TeX&svg=1)

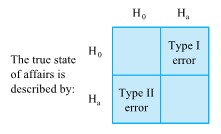

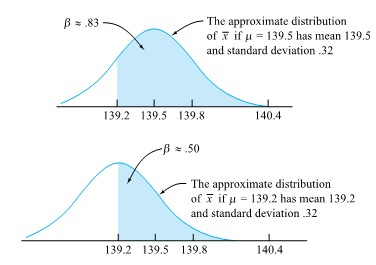

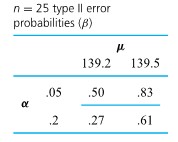

is called the power of the significance test.

is called the power of the significance test.

distribution.

distribution.

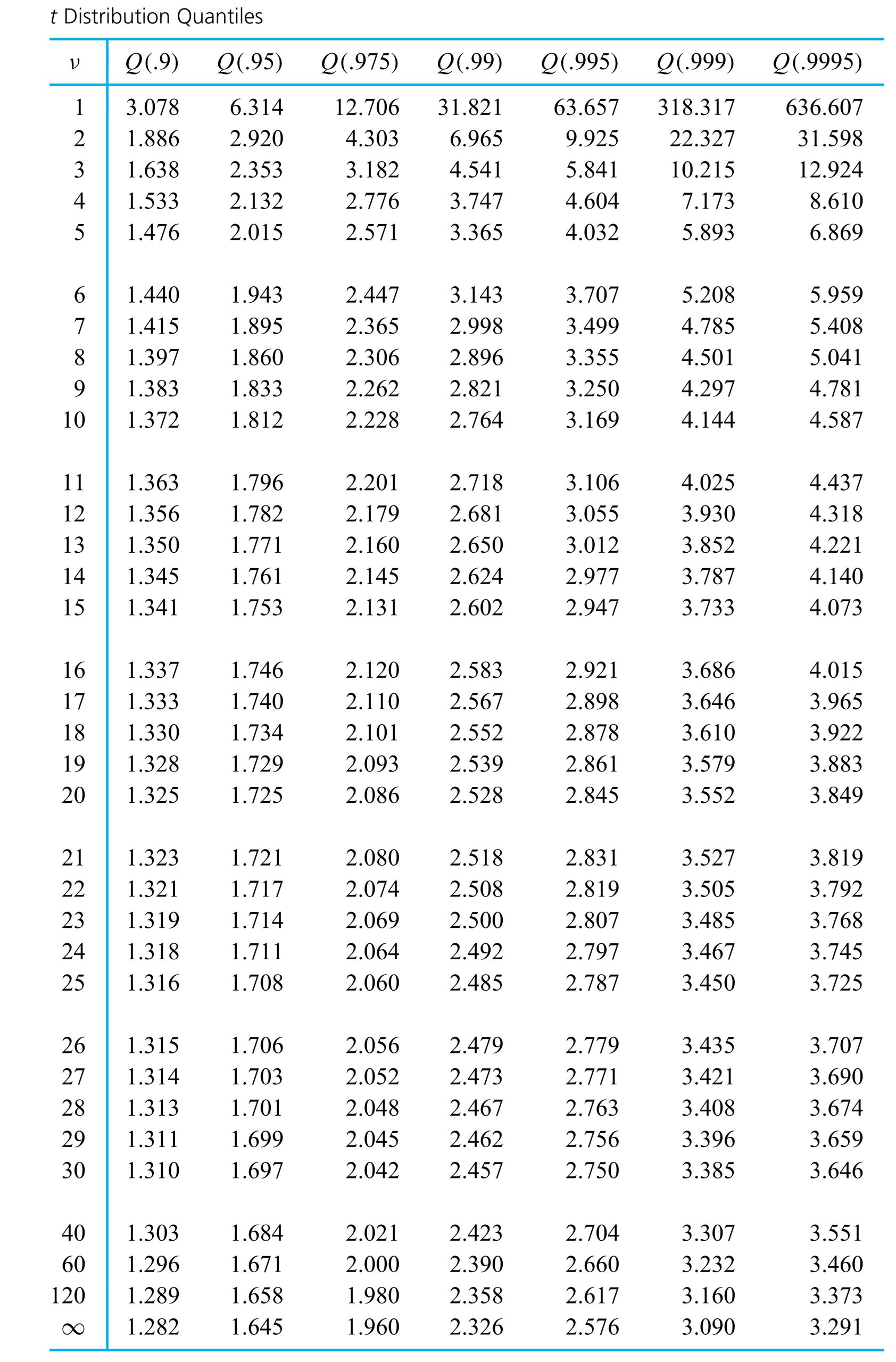

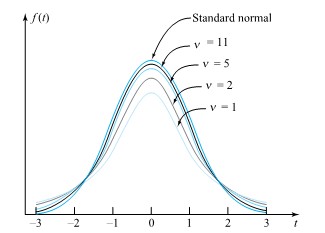

exists. Instead, it is common to use tables (or statistical software) to evaluate common t distribution quantiles and to get at least crude bounds on the types of probabilities needed in significance testing. Table A1.2 in the Appendix 1 of statistical tables is a typical table of t quantiles. Across the top of the table are several cumulative probabilities. Down the left side are values of the degrees of freedom parameter,

exists. Instead, it is common to use tables (or statistical software) to evaluate common t distribution quantiles and to get at least crude bounds on the types of probabilities needed in significance testing. Table A1.2 in the Appendix 1 of statistical tables is a typical table of t quantiles. Across the top of the table are several cumulative probabilities. Down the left side are values of the degrees of freedom parameter, ![P[T<-1.9]=P[T>1.9]=1-P[T \leq 1.9] P[T<-1.9]=P[T>1.9]=1-P[T \leq 1.9]](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5BT%3C-1.9%5D%3DP%5BT%3E1.9%5D%3D1-P%5BT%20%5Cleq%201.9%5D&fg=000000&font=TeX&svg=1)

distribution. That is,

distribution. That is,![P[T \leq 1.9] \leq .95 P[T \leq 1.9] \leq .95](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5BT%20%5Cleq%201.9%5D%20%5Cleq%20.95&fg=000000&font=TeX&svg=1)

![P[T<-1.9]<.10 P[T<-1.9]<.10](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5BT%3C-1.9%5D%3C.10&fg=000000&font=TeX&svg=1)

![P[T \leq 2.3]<.975 P[T \leq 2.3]<.975](https://atu0g9ctah.execute-api.ca-central-1.amazonaws.com/latest/latex?latex=P%5BT%20%5Cleq%202.3%5D%3C.975&fg=000000&font=TeX&svg=1)